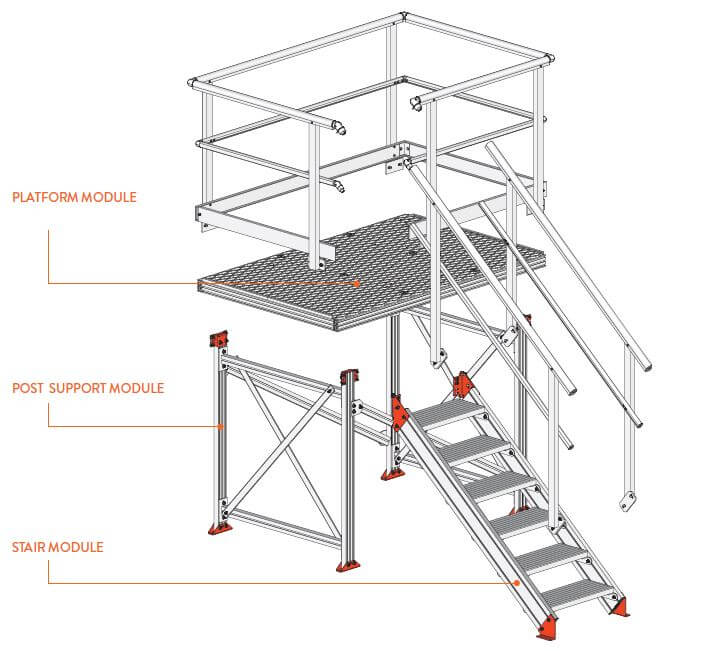

KOMBI® Stair and Platform Systems consist of three primary modules

The support module, the platform module and the stair module. Each module is available in a variety of sizes which can then be adjusted.

SMARTER - EASIER - FASTER

KOMBI® Design Purpose

- For use by construction workers, specialist trades and maintenance personnel.

- Suited to provide access to equipment in many sectors such as HVAC, industry & manufacturing, lift & elevator machinery, railway plants and stations, site sheds and solar and renewable energy farms.

KOMBI® Builda Configurator

- A cloud based 3D design tool, the KOMBI Builda created specifically to configure KOMBI systems.

- Includes KOMBI proprietary design parameters.

- Provides 3D model and front, top and side views and list of components required to build the system.

KOMBI® Proprietary System

- KOMBI is an Australian made, engineered and configured system.

- A series of live load testing and calculated parameters have determined design outcomes - read the Technical Statement.

For Design Assistance

Melbourne Office

1029 Mountain Highway,

Boronia VIC 3155

Australia

View in google maps1300 072 651

info@kombiaccess.com

- REQUEST A QUOTE

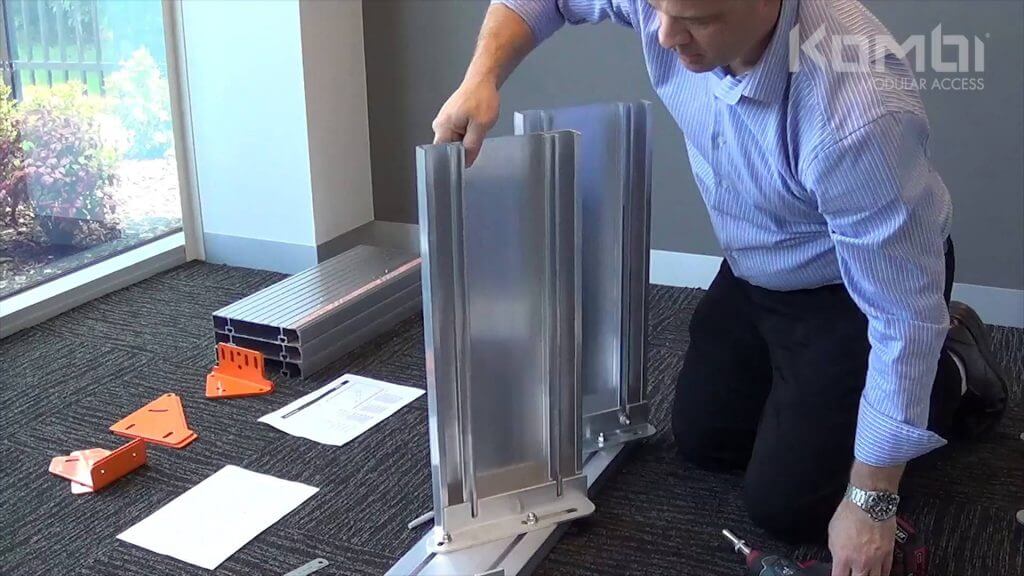

Install Videos

Play

KOMBI WEBINAR 1 - Introduction to Kombi

Play

KOMBI WEBINAR 2 - Assembling the post supports & platform

Play

KOMBI WEBINAR 3 - Assembling the stairway

Play

KOMBI WEBINAR 4 - Installing the Guardrail

Play

How To Install A Pre-Assembled KOMBI Platform

Play

When to design, install and use ladders, steps and stairs

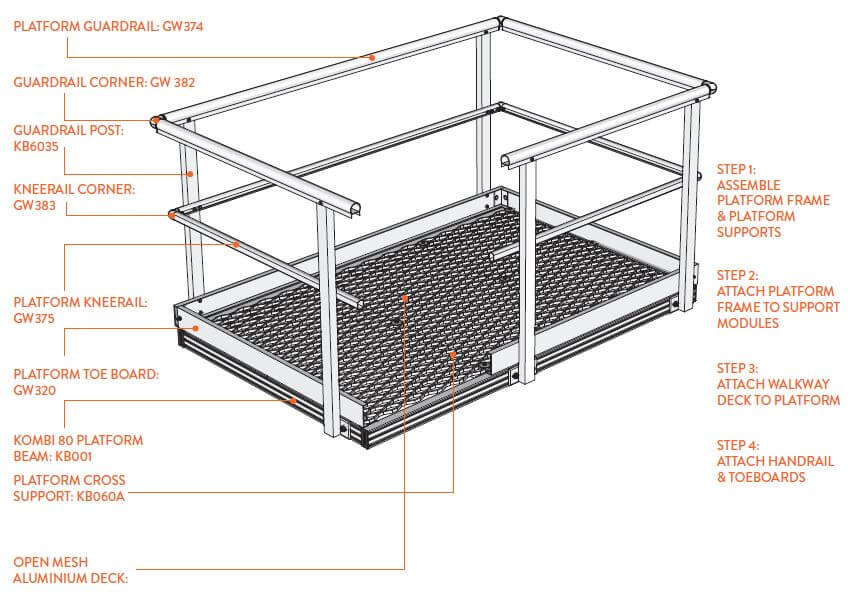

System Assembly

KOMBI® is made up of 3 primary modules

- Post support module: assembled first

- Platform module: assembled second

- Stair module: assembled third

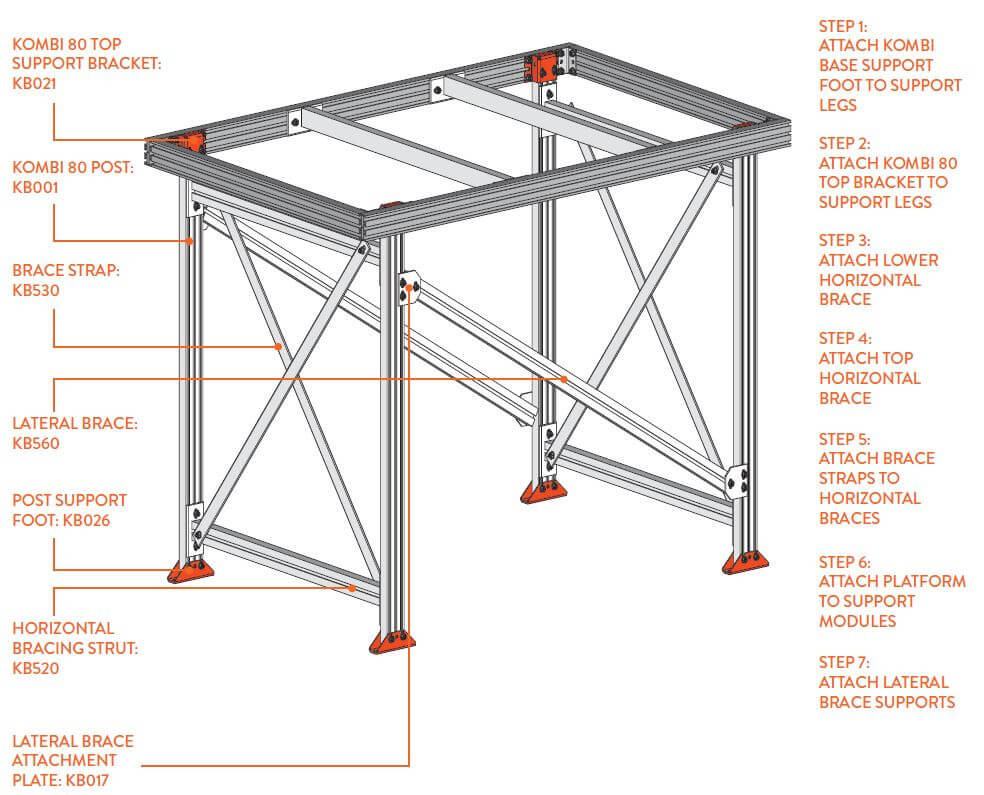

POST SUPPORT ASSEMBLY

- KOMBI post support structure is design to support a live load of 2.5kPa (250kg/m2).

- KOMBI supports are available in three standard widths 610mm, 915mm and 1220mm. Custom widths can be manufactured.

Installation Requirements

- See configuration tables for set out of horizontal braces, bracing straps and lateral braces.

- Lower horizontal brace struct KB520 is set at 150mm above bottom of post.

PLATFORM ASSEMBLY

- KOMBI Platforms are designed to support a live load of 2.5kPa (250kg/m2 distributed load).

- KOMBI Platforms are available in three standard external width dimensions 687mm, 992mm and 1297mm. Custom widths can be manufactured.

- KOMBI Platforms can be joined together to create larger decks where required.

- For dead loads such as an aircon unit, pallets etc please consult with the SAYFA design team to confirm correct configuration.

Installation Requirements

- Platform mesh aperture to be a maximum of 15mm where persons have access to or work beneath the platform. The GW334 narrow width deck to be used in this application.

- Guardrail posts to be space dat a maximum of 2000mm centres.

- Maximum dimensions between underside of handrail to top of kneerail is 450mm.

- Platform toe board is required where an object could fall from the platform onto an area to which access by persons is a possibility. Maximum gap between toe board and deck is 10mm.

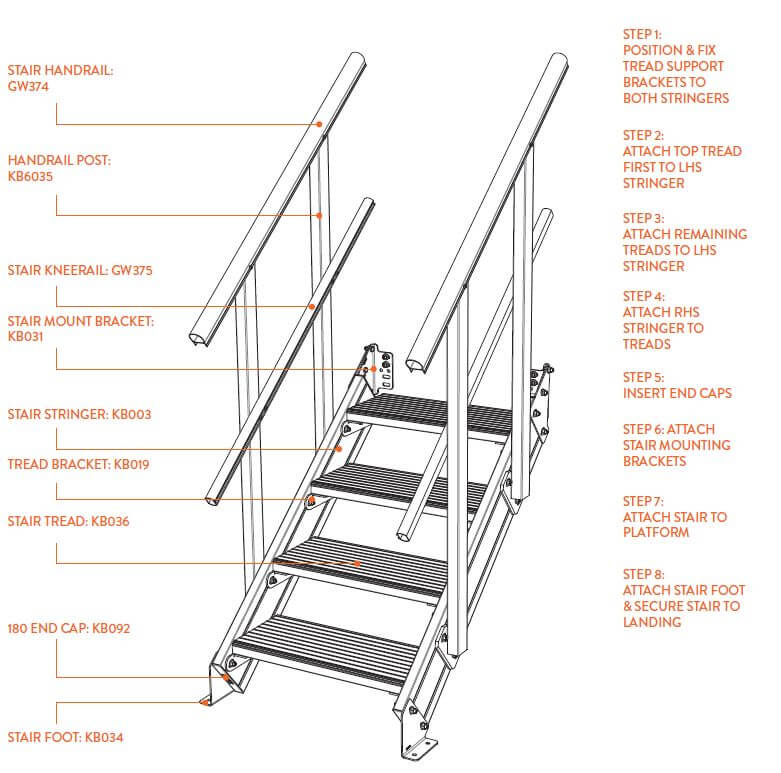

STAIR ASSEMBLY

- KOMBI Stairs are designed to support a load of 2.5kPa live load (250kg/m2).

- KOMBI Stairs are designed to best suit a 40 degree angle however are suitable angles from 25 - 45 degrees.

- KOMBI Stairs are available in three standard widths: 610mm, 915mm & 1220mm. Custom widths can be manufactured.

Installation Requirements

- Minimum inside distance between stair stringers to be not less than 600mm.

- Clear space between handrails/kneerails to be no less than 550mm.

- The number of treads in a flight must not be less than 2 or greater than 17.

- Treads are allowed maximum of 5mm variation in spacing as per AS1657:2018.

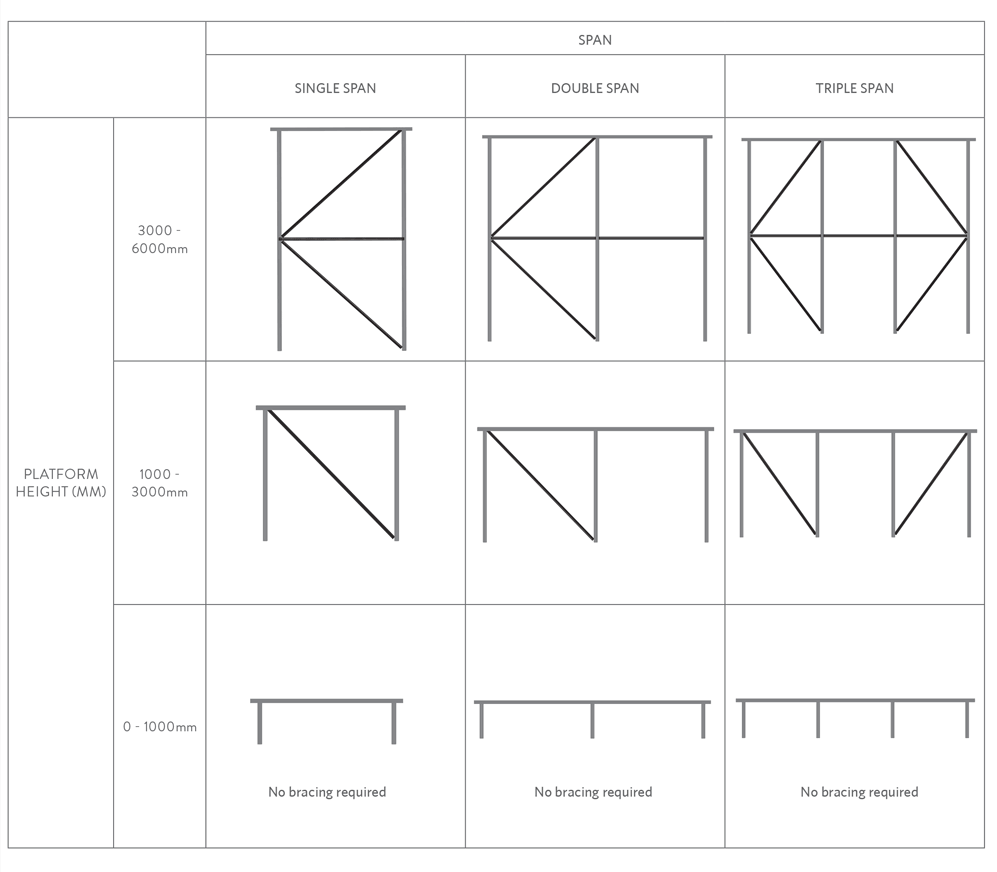

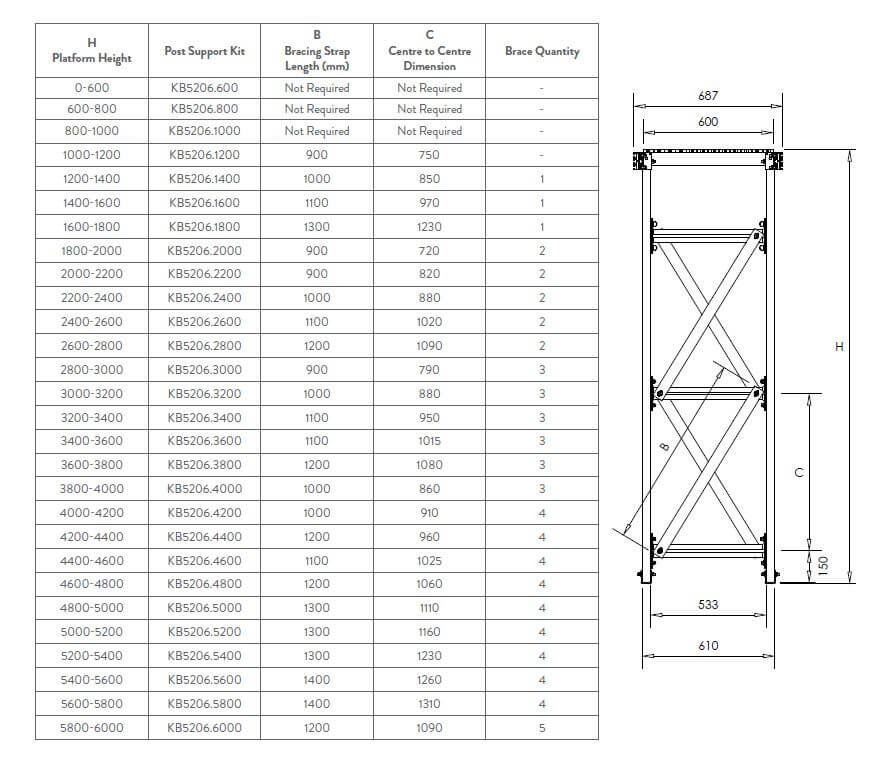

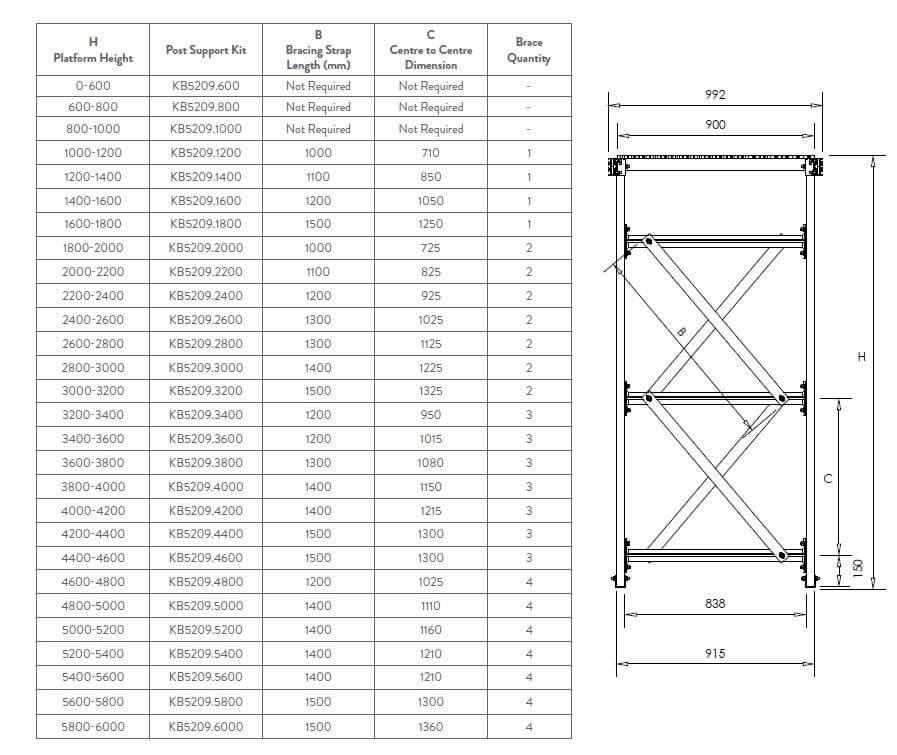

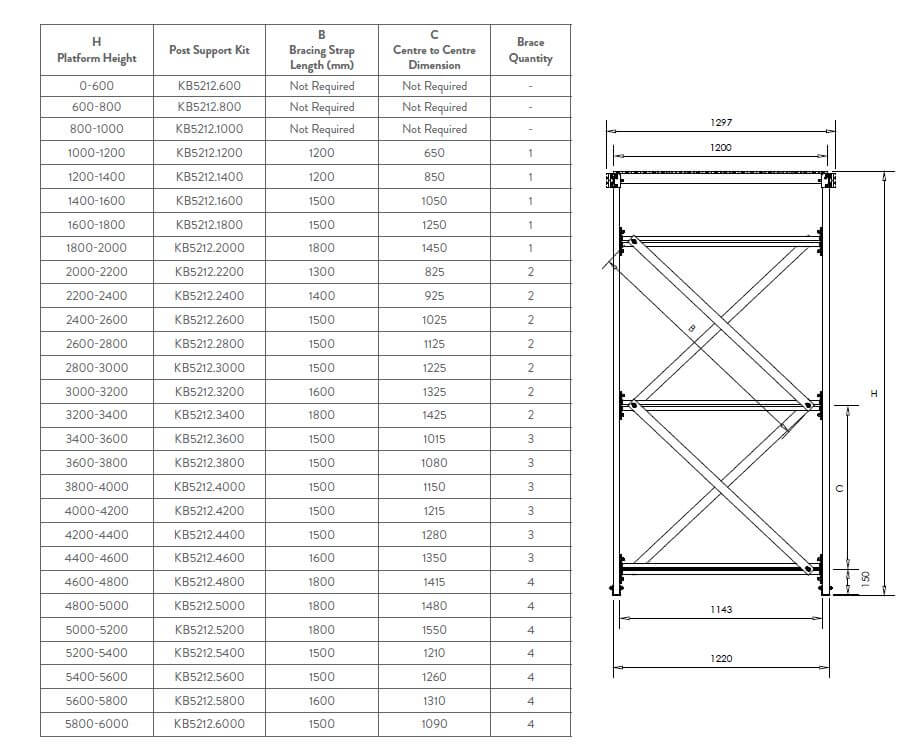

Post Support Bracing Layout

Instructions For Layout

- Step 1: Identify correct post height.

- Step 2: Determine correct post support kit.

- Step 3: Assemble post support bracing as per tables below.

900 Series Bracing Layout

1200 Series Bracing Layout

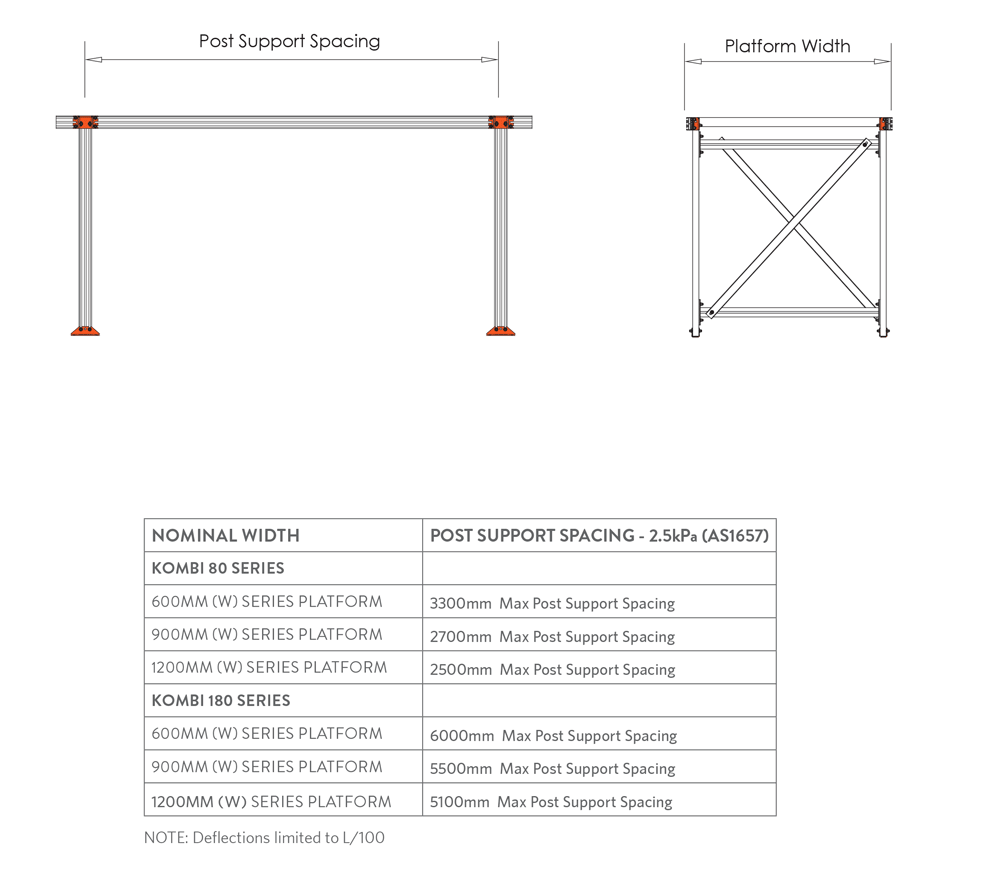

Post Support Span Table

Post Support Spacing Information

- KOMBI Platforms are designed to support a live load of 2.5kPa (250kg/m2).

- Calculations assume maximum flooring mass of 12kg/m2 (weight of guardrail and aluminium deck).

- Allowance for floor vibration has not been taken into account in design.

- Platform deflection has been based on two variables, frequent access (less deflection) and infrequent access (greater deflection). Table below shows post spacings based on above.

- Lateral bracing is required as per configuration tables.

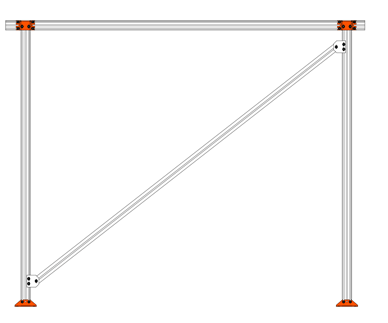

Lateral Brace Layout

Lateral Brace Installation

Lateral Brace Installation

- KOMBI Platform proprietary design allows freestanding platforms of up to 6000mm.

- Platforms above 3000mm require a horizontal brace mid span of the post in all bays.

- For longer platforms exceeding triple span, up to 30m, lateral bracing is require in the first and last bay only.

- For longer platforms from 30m - 50m, lateral bracing is required in the first, centre and last bay only.

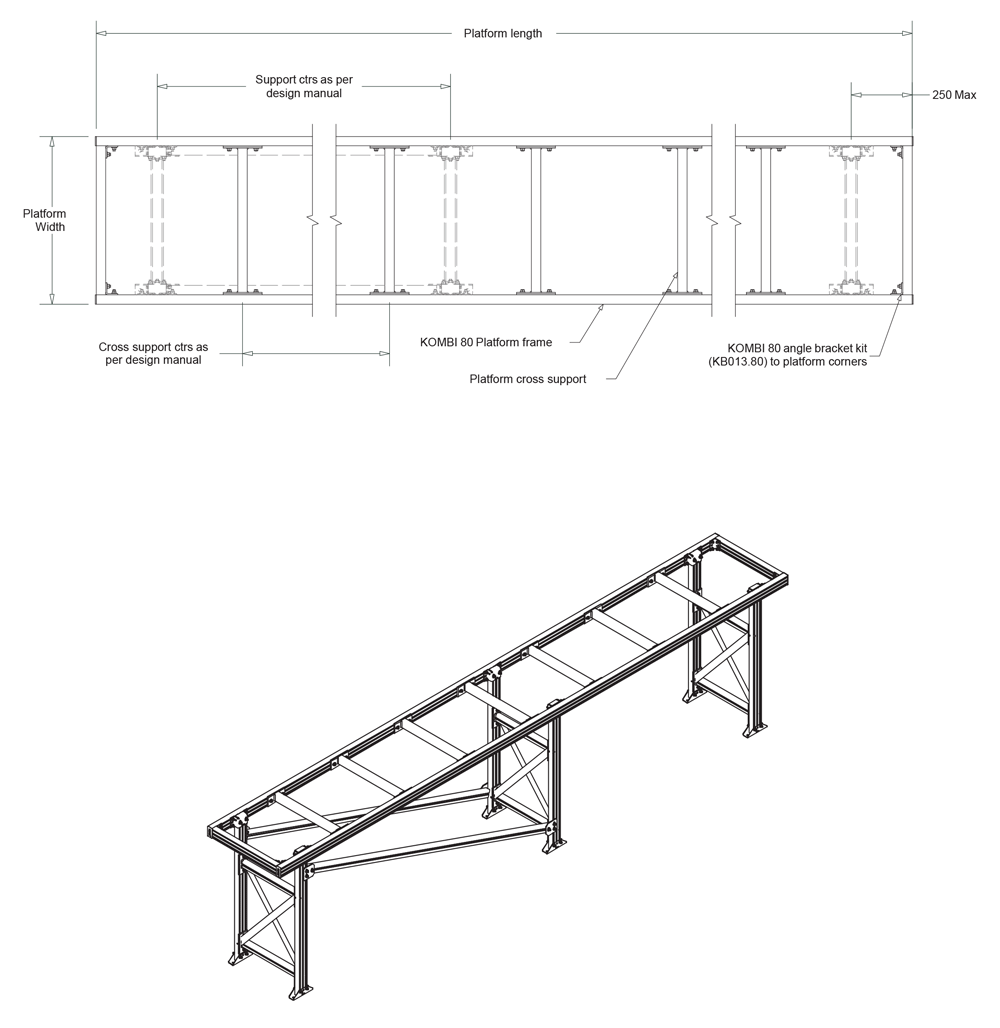

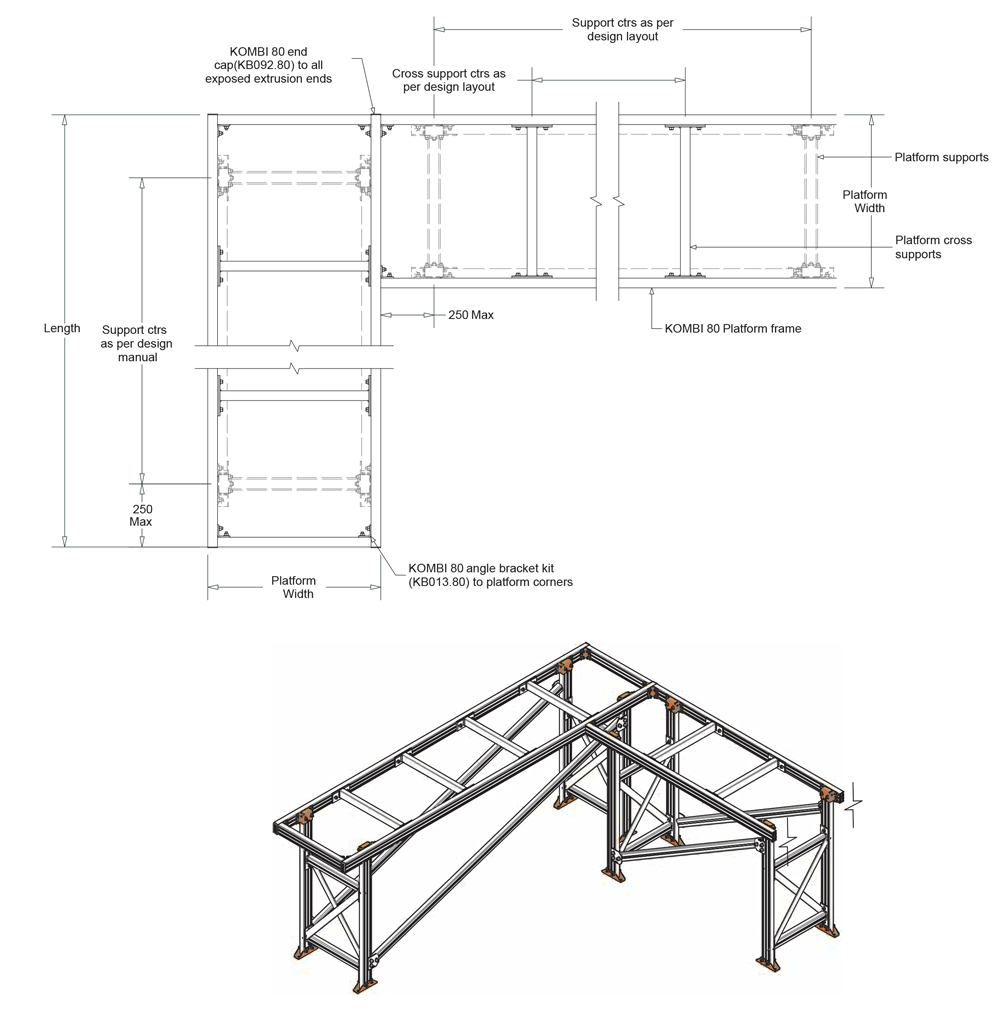

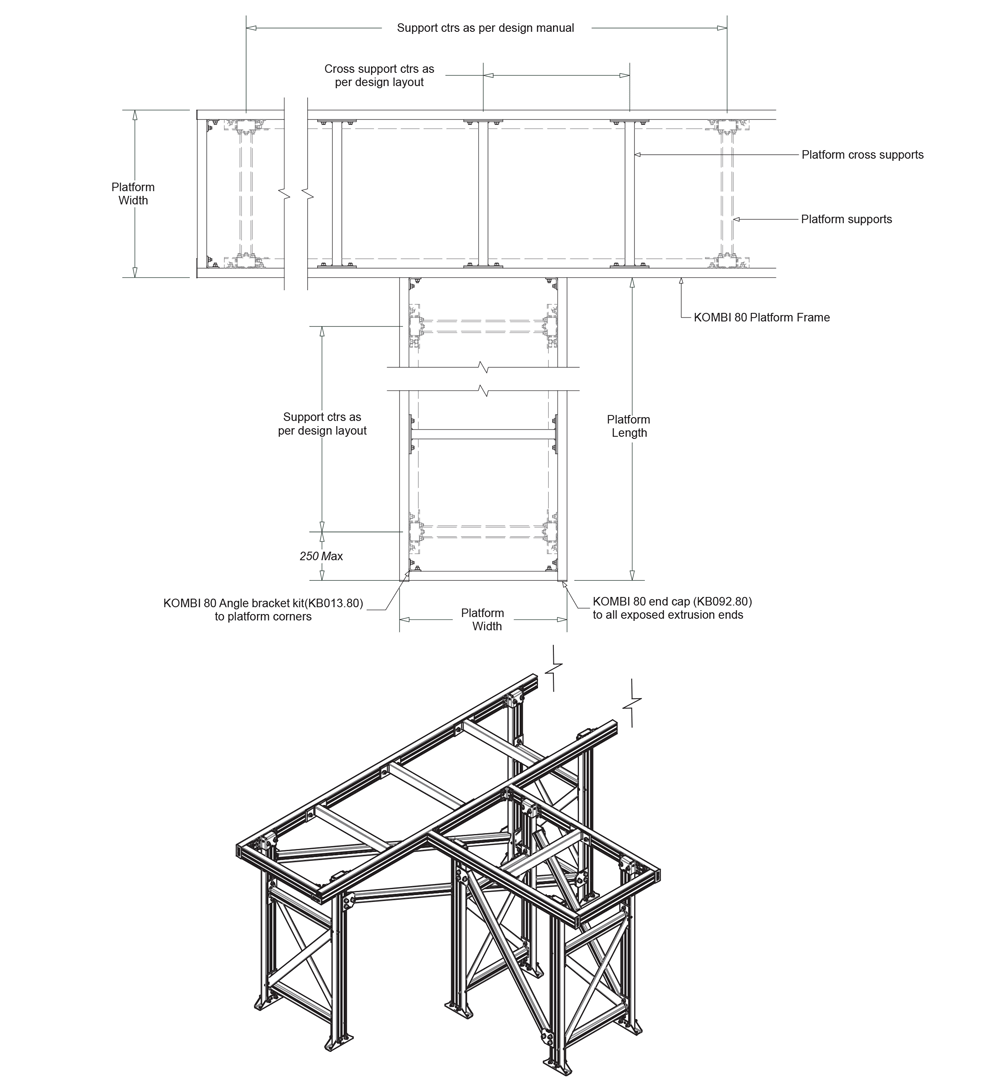

Platform Configuration

Platform Set Out Guidelines

- Platform cross supports positioned at 600mm centres.

- Post supports positioned as close to end of platform as possible. (250mm max from outside edge of platform to centre of post.)

Platform Set Out Guidelines

- Platform cross supports positioned at 600mm centres.

- Post supports positioned as close to end of platform as possible. (250mm max from outside edge of platform to centre of post.)

Platform Set Out Guidelines

- Platform cross supports positioned at 600mm centres.

- Post supports positioned as close to end of platform as possible. (250mm max from outside edge of platform to centre of post.)

Lateral Brace Installation

Lateral Brace Installation