KOMBI® Modular Aluminium Access Stairs and Access Platforms - Australian designed and manufactured

The entire system can be configured to suit any size, height or shape that is required. Designed for speed, built for strength.

SMARTER - EASIER - FASTER

For Design Assistance

Melbourne Office

1029 Mountain Highway,

Boronia VIC 3155

Australia

View in google maps1300 072 651

info@kombiaccess.com

- REQUEST A QUOTE

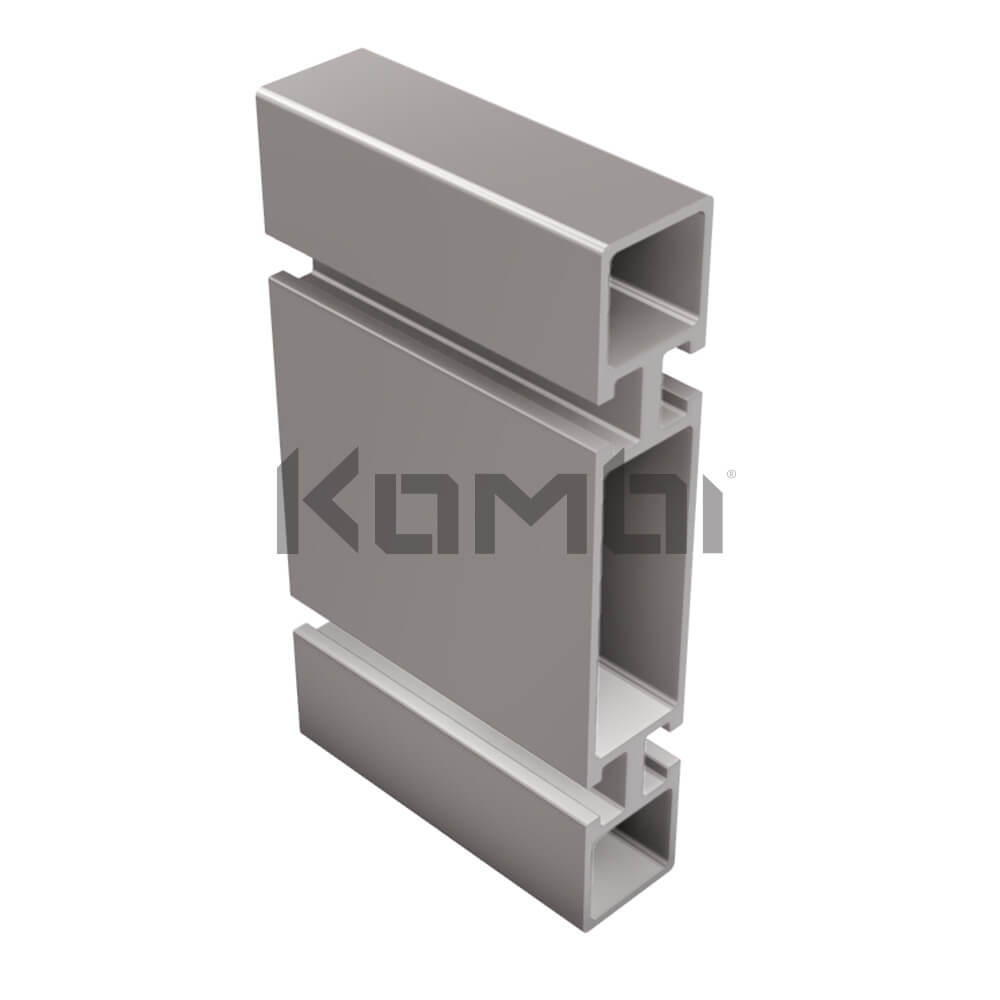

KOMBI® Extrusion

The primary construction being extruded aluminium makes it lightweight and easy to maneouvre. KOMBI extrusions are cut to standard lengths which can then be trimmed to suit on-site. A series of T slots in the extrusion allows easy adjustment and positioning of brackets.

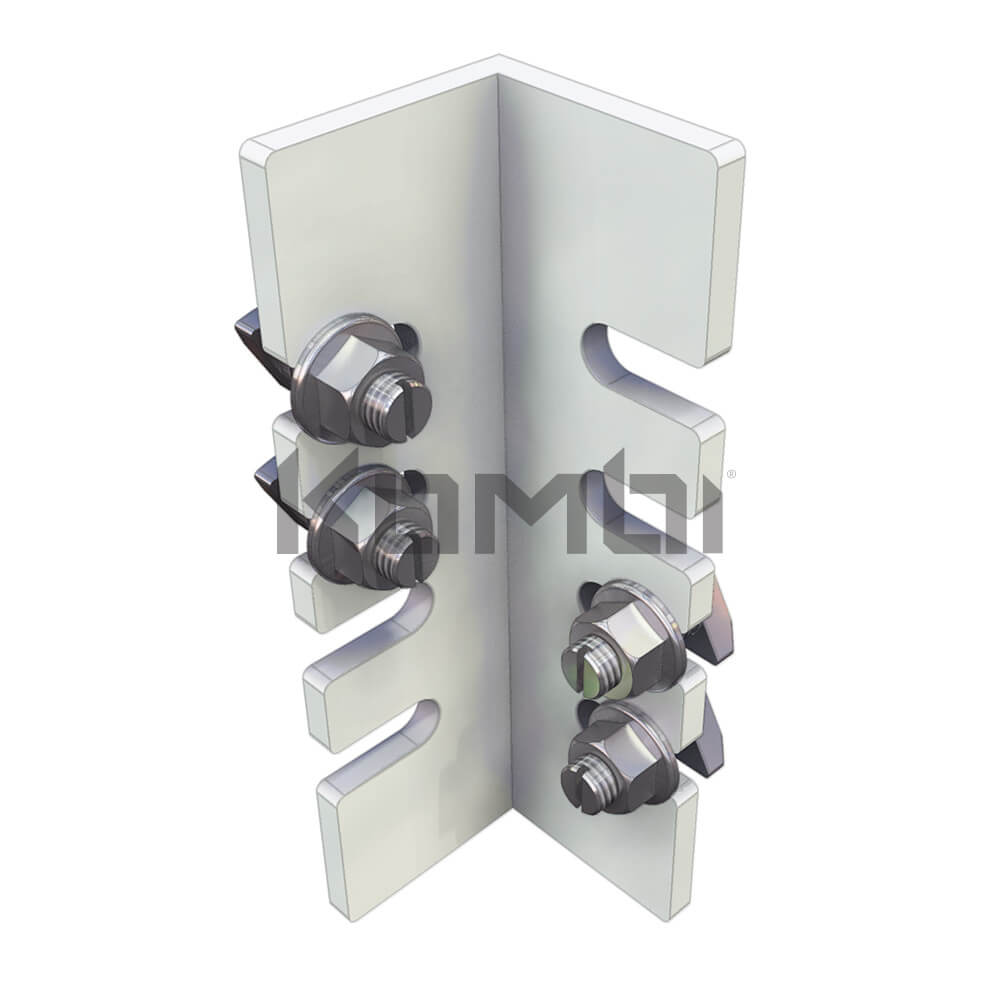

KOMBI® Brackets

Manufactured from 316 stainless steel, the KOMBI brackets provide the primary connection for all extrusions. A slot in the plate allows insertion of the T-Bolt through the plate and into the extrusion.

KOMBI® End Caps

All extrusions are finished off with plastic moulded end caps to ensure insects and contamination are avoided.

The KOMBI® Secret

Providing safe access to large sites can be costly and in times of an uncertain economy, large financial outlays may be difficult. Alternatively there may be existing systems which need additional or new components but with traditional welded steel products how do you combine systems?

There had to be a better way!

KOMBI's modular components enable total flexibility with system design. If you need to start small and then progressively expand when time and finances permit, no problems. As the components do not require welding and use only standard tools, additional components can be added in-situ, around and beside existing plant and equipment with minimal disruptions.

Build your own or send through a request to our KOMBI Customer Service Team - it's that simple!

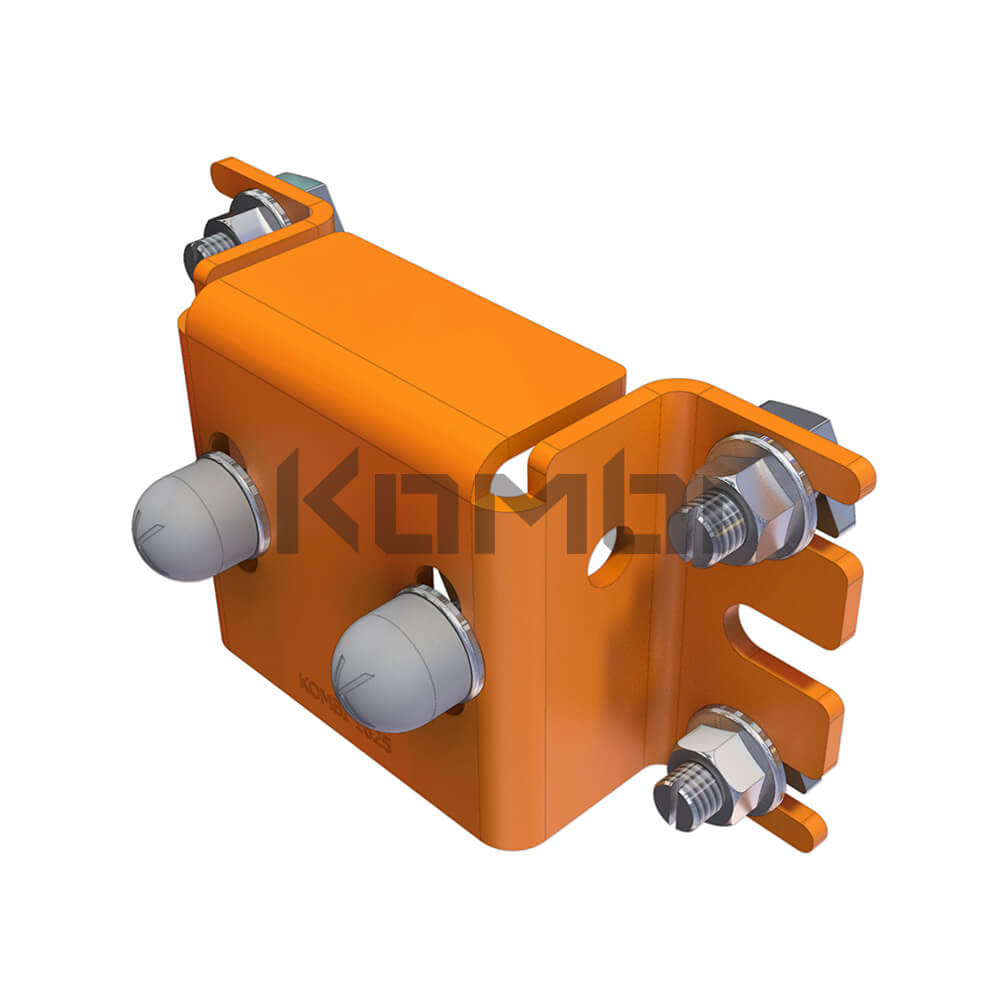

KOMBI® T-Bolt Technology

Components

KOMBI 80 Extrusion

Code

KB001.6000

80 x 38mm - 6000mm

Material

Aluminium

Use

Support beam for platform

KOMBI 180 Extrusion

Code

KB003.6000

180 x 32mm - 6000mm

Material

Aluminium

Use

Support beam for platform

KOMBI Joist To Bearer Bracket

Code

KB004

Material

Aluminium

Use

Connects KOMBI 80 joist to bearers

KOMBI T-Bolt (M10)

Code

KB005

Material

Stainless Steel

Use

Fixes all brackets & plates in the KOMBI system

KOMBI T-Bolt Nut Cap

Code

KB005-C

Material

Hi density plastic

Use

Caps all exposed T-Bolt ends

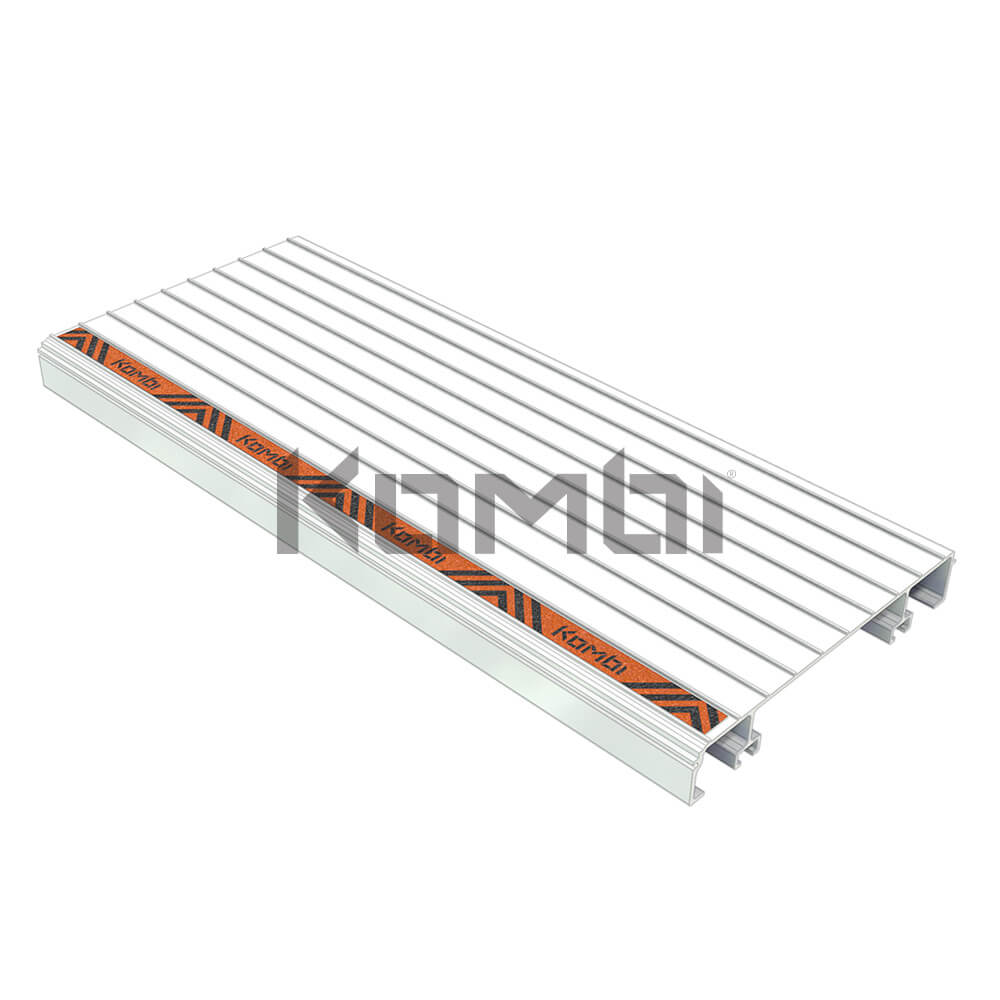

KOMBI Stair Tread

Code

KB010.0610 (600 Series) - 610mm

KB010.0915 (900 Series) - 915mm

KB010.1220 (1200 Series) - 1220mm

Material

Aluminium

Use

Stair tread for modular stair system

KOMBI 80 Horizontal Support Bracket

Code

KB012

Material

Powder coated stainless steel

Use

Fixes platform cross supports to platform stringers

KOMBI 80 Angle Bracket

Code

KB013.80

Material

Powder coated stainless steel

Use

90 degree KOMBI 80 corners

KOMBI 180 Angle Bracket

Code

KB013.180

Material

Powder coated stainless steel

Use

90 degree KOMBI 180 corners

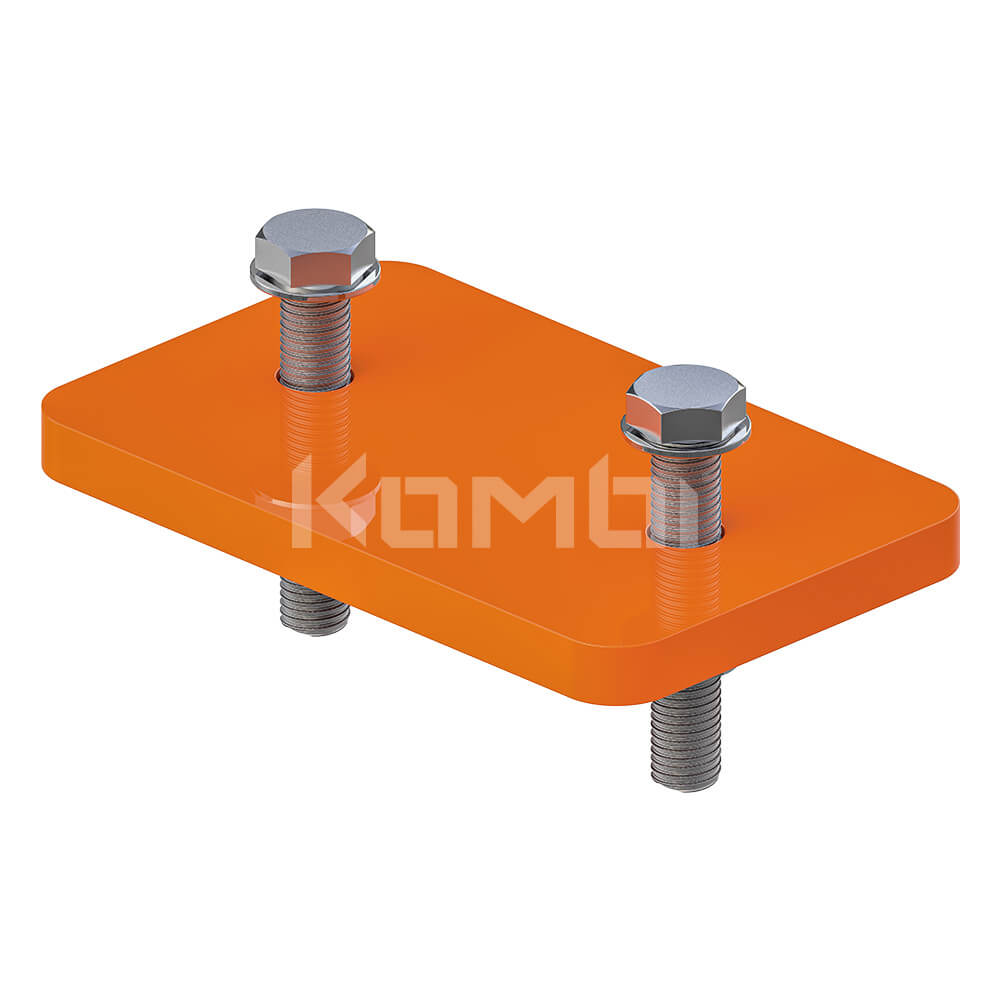

KOMBI Stair Bridge Mounting Plate

Code

KB014

Material

Powder coated stainless steel

Use

Connects stair stringer to platform structure

KOMBI 80 Angle Bracket Kit 45 Degrees

Code

KB015.80

Material

Powder coated stainless steel

Use

KOMBI 45 degree angle corners

KOMBI 80 Post Joining Plate

Code

KB016.80

Material

Aluminium

Use

Joins KOMBI 80 extrusion

KOMBI 180 Joining Plate

Code

KB016.180

Material

Aluminium

Use

Joins KOMBI 180 extrusion

KOMBI Lateral Brace Plate Kit

Code

KB017

Material

Aluminium

Use

Connects horizontal bracing

KOMBI Bracing Angle Kit

Code

KB018

Material

Aluminium

Use

Connects angled bracing

KOMBI 80 Stair Tread Connection Bracket Kit

Code

KB019

Material

Aluminium

Use

Joins KOMBI 80 extrusion

KOMBI 80 Top Support Bracket

Code

KB021

Material

Powder coated stainless steel

Use

Connects KOMBI 80 post to platform

KOMBI 80 Post Through Bracket

Code

KB022

Material

Powder coated stainless steel

Use

Connects KOMBI 80 post to platform

KOMBI 80 Base Support Foot

Code

KB026

Material

Powder coated stainless steel

Use

Secures KOMBI post to ground

KOMBI 80 Stair Adjustable Bracket

Code

KB031

Material

Powder coated stainless steel

Use

Connects stair stringer to platform structure

KOMBI 80 Stair to Platform Bracket Kit

Code

KB032

Material

Aluminiuum

Use

Attaches base of stair KB026 to side of platform

KOMBI 80 Stair Adjustable Bracket

Code

KB033

Material

Aluminium

Use

Sandwich plate for KB034 through mesh attachment

KOMBI Stair Bridge Mounting Plate

Code

KB034

Material

Powder coated stainless steel

Use

Connects stair stringer to platform structure

KOMBI Platform Cross Support

Code

KB060.06 - 600mm

KB060.09 - 900mm

KB060.12 - 1200mm

Material

Aluminium

Use

Supports aluminium platform

KOMBI Platform Cross Support, Adjustable

Code

KB060A.06 - 600mm

KB060A.09 - 900mm

KB060A .12 - 1200mm

Material

Aluminium with stainless steel brackets

Use

Supports aluminium platform

KOMBI 80 End Cap

Code

KB092.80

Material

High density plastic

Use

Caps exposed ends of KOMBI 80 extrusion

KOMBI 180 End Cap

Code

KB092.180

Material

High density plastic

Use

Caps exposed ends of KOMBI 180 extrusion

KOMBI Support Brace

Code

KB530

Material

Aluminium

Use

Provides lateral stability for platform

KOMBI Stair Post Kit, Left Hand

Code

KB60L

Material

Aluminium

Use

Stair post for handrail

KOMBI Stair Post Kit, Right Hand

Code

KB601R

Material

Aluminium

Use

Stair post for handrail

KOMBI 1106

Code

KB1106 (600 Series) - 600 - 4000mm (H)

KB1109 (900 Series) - 1000 - 4000mm (H)

KB1112 (1200 Series) - 1000 - 4000mm (H)

Material

Aluminium / Powder coated stainless steel

Note

Sold in 200mm increments

KOMBI Cantilever Bracket

Code

KB5506 (600 Series) - 600 - 6000mm (L)

KB5509 (900 Series) - 600 - 6000mm (L)

KB5512 (1200 Series) - 600 - 6000mm (L)

Material

Aluminium / Powder coated stainless steel

Note

To suit KOMBI 80 or 180 Platform for concrete or metal cladding structures. Fixings to structure not included.

KOMBI Platform Narrow Mesh

Code

GW334

Material

Aluminium

Use

Provides walkway deck for platforms. Small opening minimises possibility of objects falling through mesh.

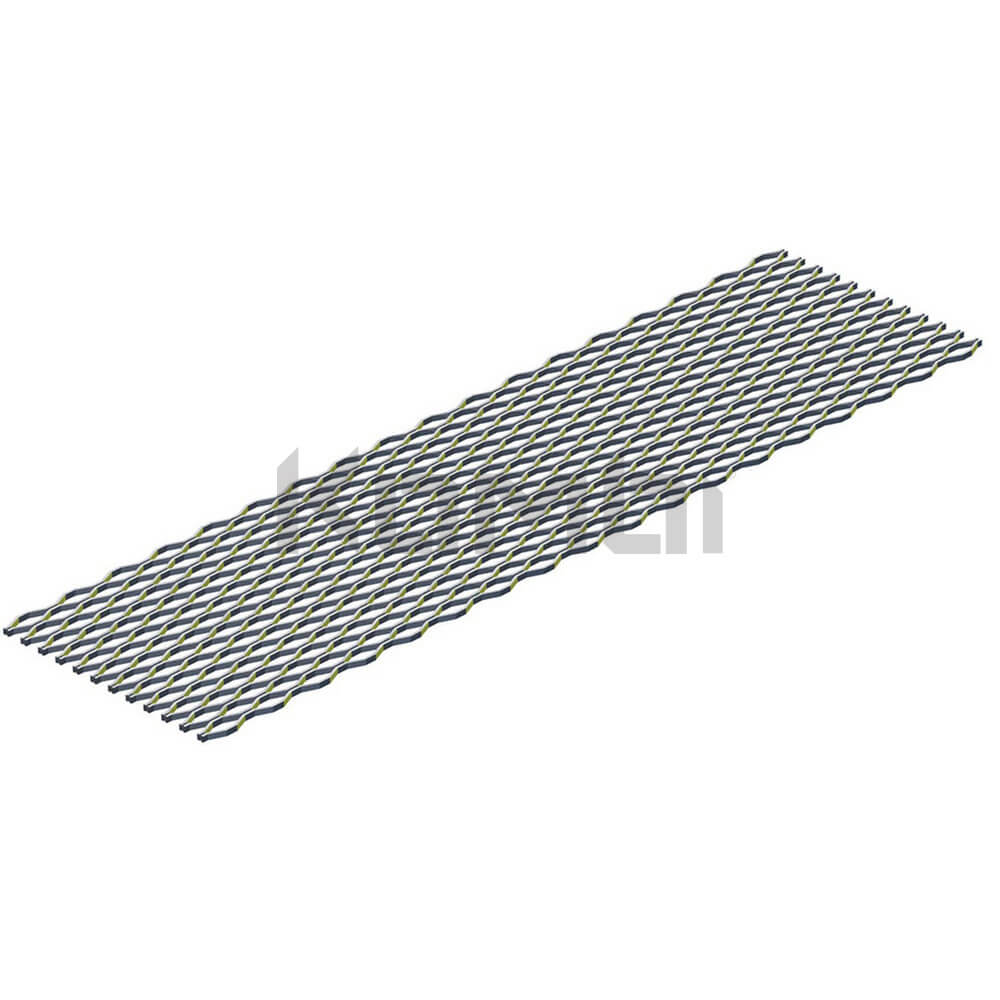

KOMBI Platform Standard Mesh

Code

GW335

Material

Aluminium

Use

Provides walkway deck for platforms

KOMBI Walkway Fixing Disc

Code

GW338

Material

Aluminium

Use

Secures walkway to platform

KOMBI Walkway Screw Fixing 12-14 x 35mm

Code

SD907.35

Material

Stainless steel

Use

Secures walkway to platform

KOMBI Handrail

Code

GW374

Material

Aluminium

Use

Platform handrail section

KOMBI Kneerail

Code

GW375

Material

Aluminium

Use

Platform kneerail section

KOMBI Handrail End Cap

Code

GW378

Material

Aluminium

Use

Caps exposed ends of handrail section

KOMBI Kneerail End Cap

Code

GW379

Material

Aluminium

Use

Caps exposed ends of kneerail section

KOMBI Handrail Elbow, Adjustable

Code

GW382

Material

Aluminium

Use

Joins handrail extrusion

KOMBI Kneerail Elbow, Adjustable

Code

GW383

Material

Aluminium

Use

Joins kneerail extrusion

KOMBI Certification Label

Code

SD970.KOMBI

Material

Aluminium

Use

Provides installation details

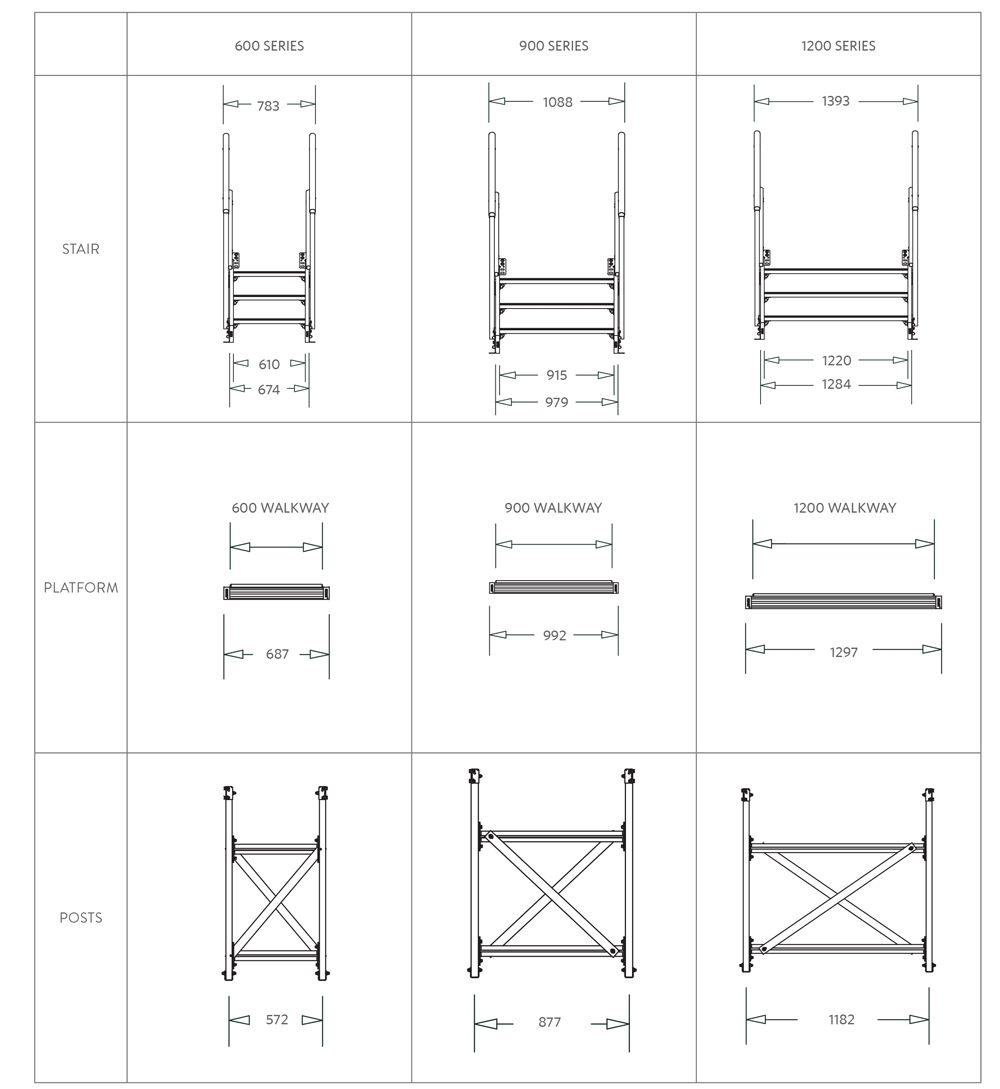

Dimensions

KOMBI® Systems are available in 3 standard widths

600 series, 900 series and 1200 series. Exact dimensions are shown below.

Custom widths can be designed and built to suit specific site requirements. (Additional lead times may be required.)