- Home

- Technical Information

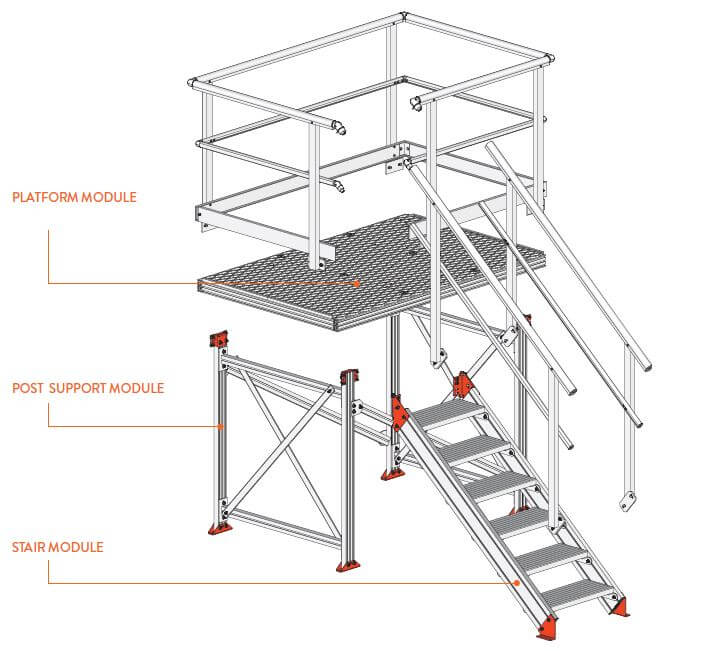

KOMBI® Stair and Platform Systems consist of three primary modules designed in accordance with AS 1657 and AS/NZS 1170 under live load conditions

The support module, the platform module and the stair module. Each module is available in a variety of sizes which can then be adjusted.

SMARTER - EASIER - FASTER

Install Videos

System Assembly

KOMBI® is made up of 3 primary modules

- Post support module: assembled first

- Platform module: assembled second

- Stair module: assembled third

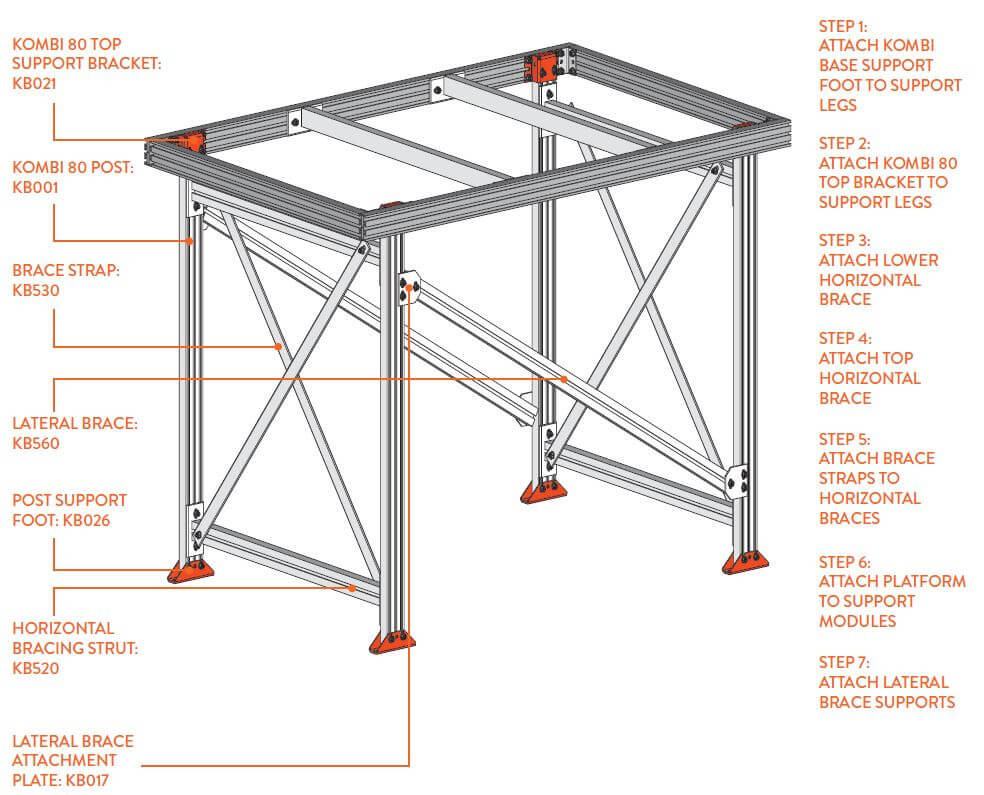

POST SUPPORT ASSEMBLY

- KOMBI post support structure is design to support a live load of 2.5kPa (250kg/m2).

- KOMBI supports are available in three standard widths 610mm, 915mm and 1220mm. Custom widths can be manufactured.

Installation Requirements

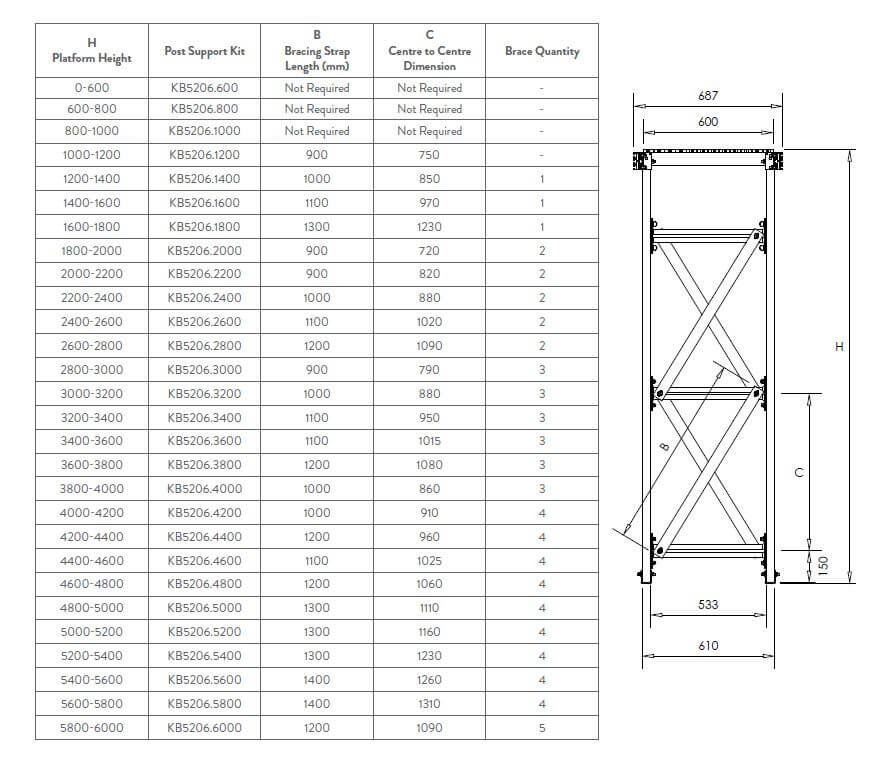

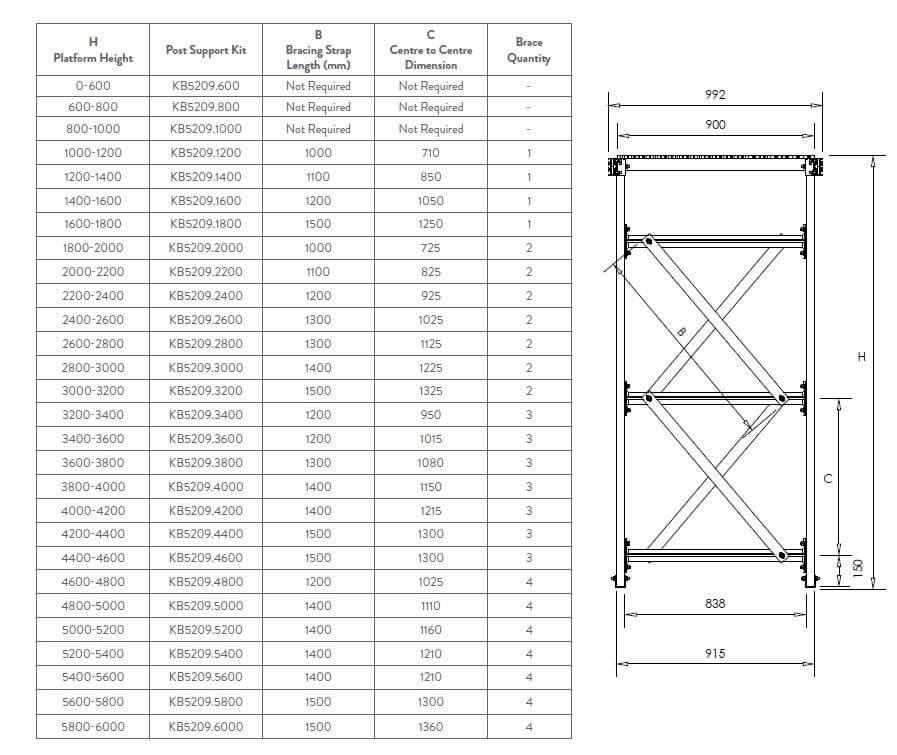

- See configuration tables for set out of horizontal braces, bracing straps and lateral braces.

- Lower horizontal brace struct KB520 is set at 150mm above bottom of post.

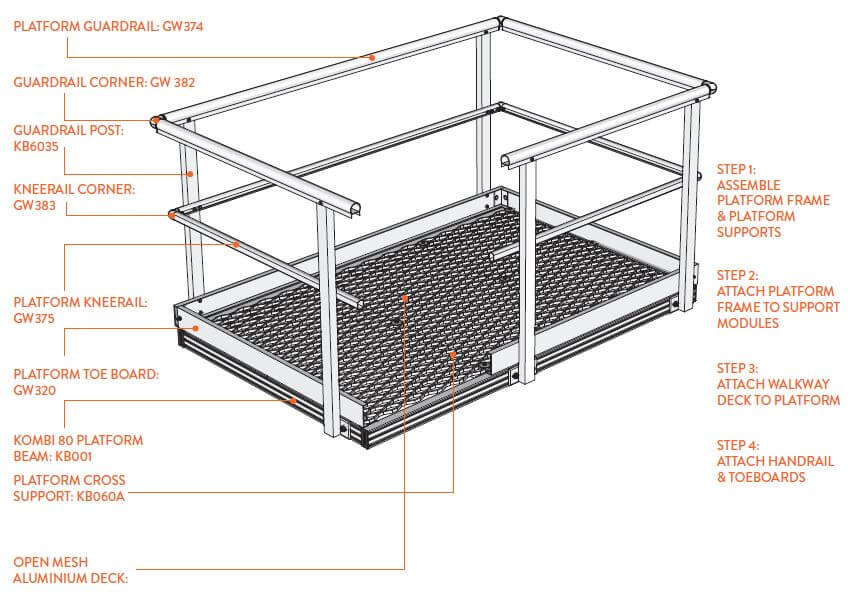

PLATFORM ASSEMBLY

- KOMBI Platforms are designed to support a live load of 2.5kPa (250kg/m2 distributed load).

- KOMBI Platforms are available in three standard external width dimensions 687mm, 992mm and 1297mm. Custom widths can be manufactured.

- KOMBI Platforms can be joined together to create larger decks where required.

- For dead loads such as an aircon unit, pallets etc please consult with the SAYFA design team to confirm correct configuration.

Installation Requirements

- Platform mesh aperture to be a maximum of 15mm where persons have access to or work beneath the platform. The GW334 narrow width deck to be used in this application.

- Guardrail posts to be space dat a maximum of 2000mm centres.

- Maximum dimensions between underside of handrail to top of kneerail is 450mm.

- Platform toe board is required where an object could fall from the platform onto an area to which access by persons is a possibility. Maximum gap between toe board and deck is 10mm.

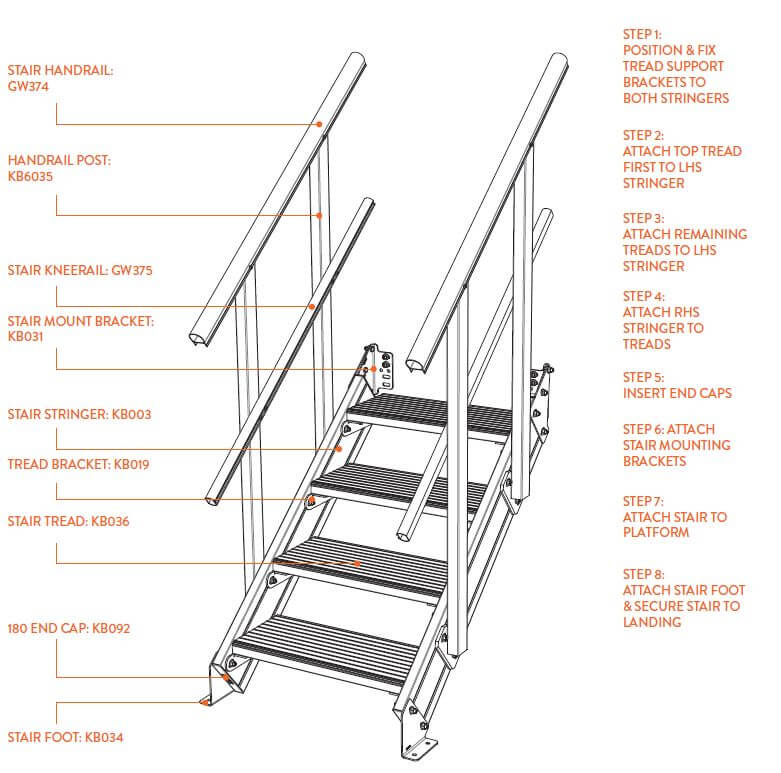

STAIR ASSEMBLY

- KOMBI Stairs are designed to support a load of 2.5kPa live load (250kg/m2).

- KOMBI Stairs are designed to best suit a 40 degree angle however are suitable angles from 25 - 45 degrees.

- KOMBI Stairs are available in three standard widths: 610mm, 915mm & 1220mm. Custom widths can be manufactured.

Installation Requirements

- Minimum inside distance between stair stringers to be not less than 600mm.

- Clear space between handrails/kneerails to be no less than 550mm.

- The number of treads in a flight must not be less than 2 or greater than 17.

- Treads are allowed maximum of 5mm variation in spacing as per AS1657:2018.

Connection Details

KOMBI Joist to Bearer Bracket

Code

KB004

Material

Aluminium

Use

Connects KOMBI 80 joist to bearers

KOMBI 80 Horizontal Support Bracket

Code

KB012

Material

Powder coated stainless steel

Use

Fixes platform cross supports to platform stringers

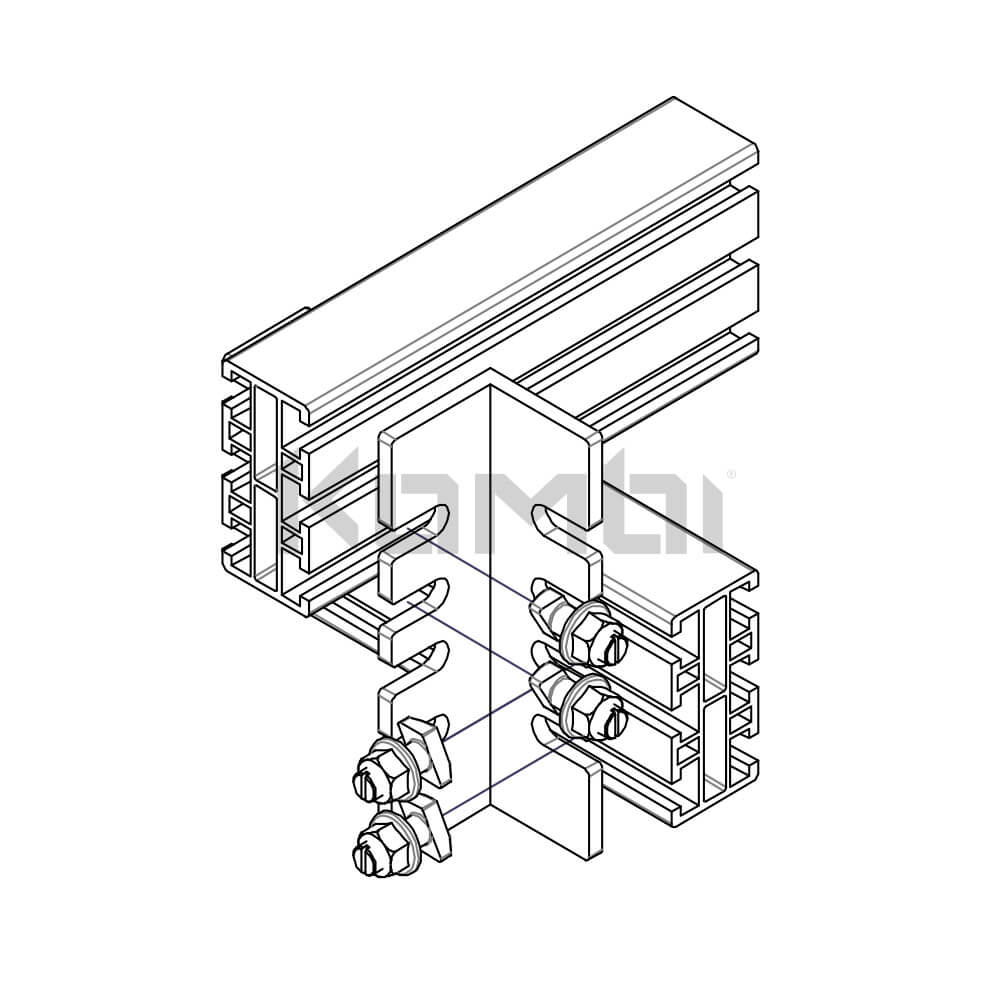

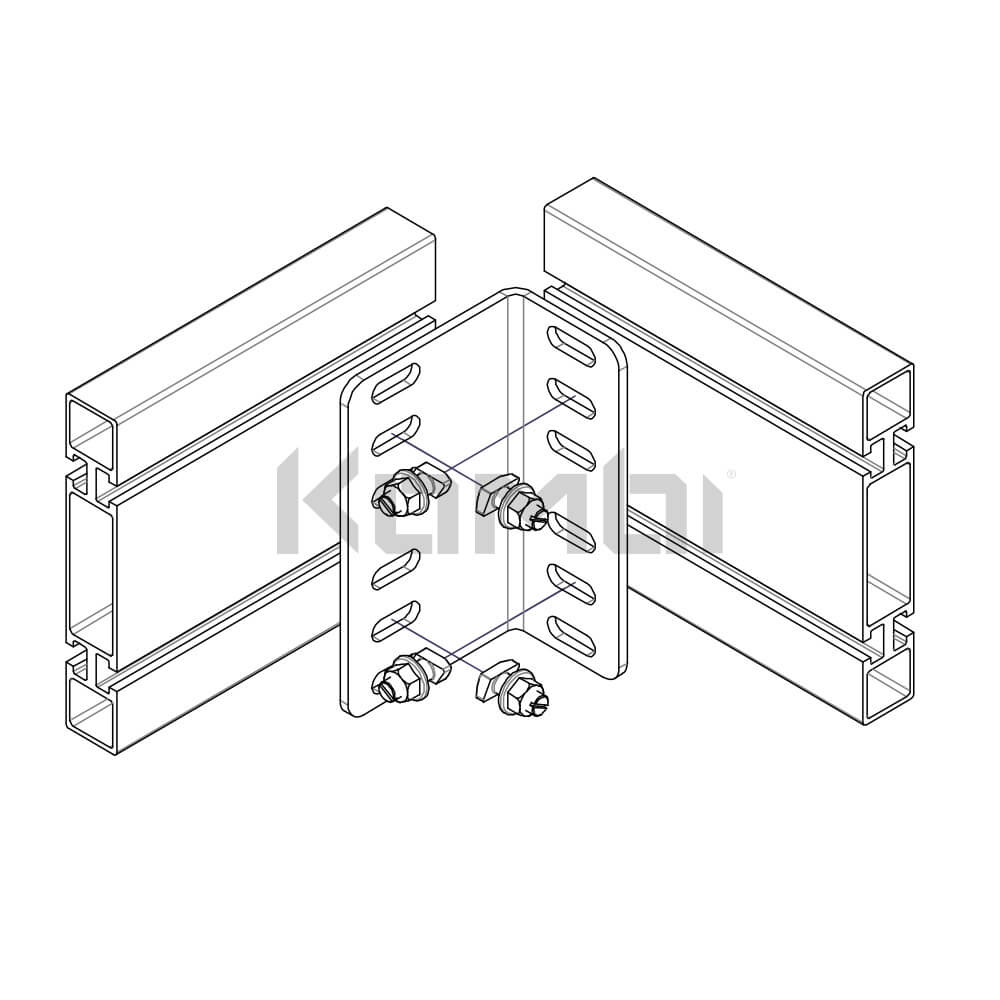

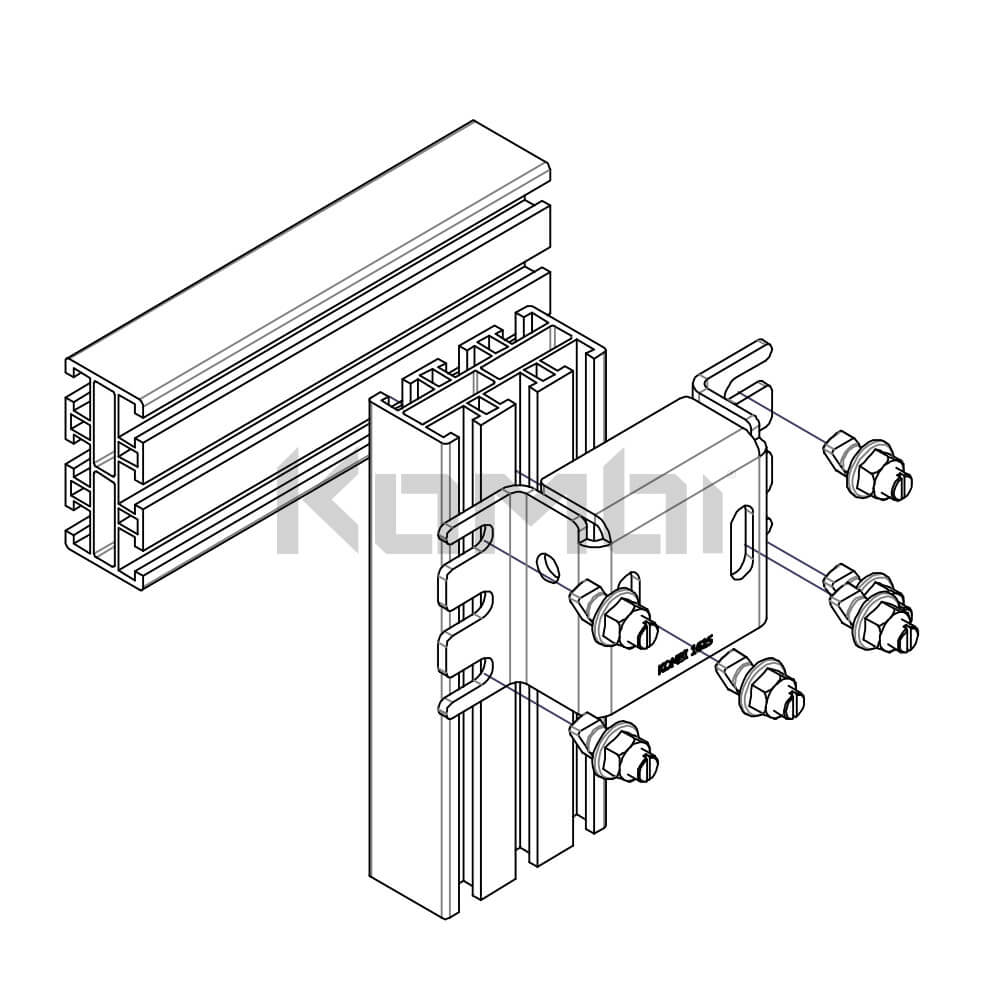

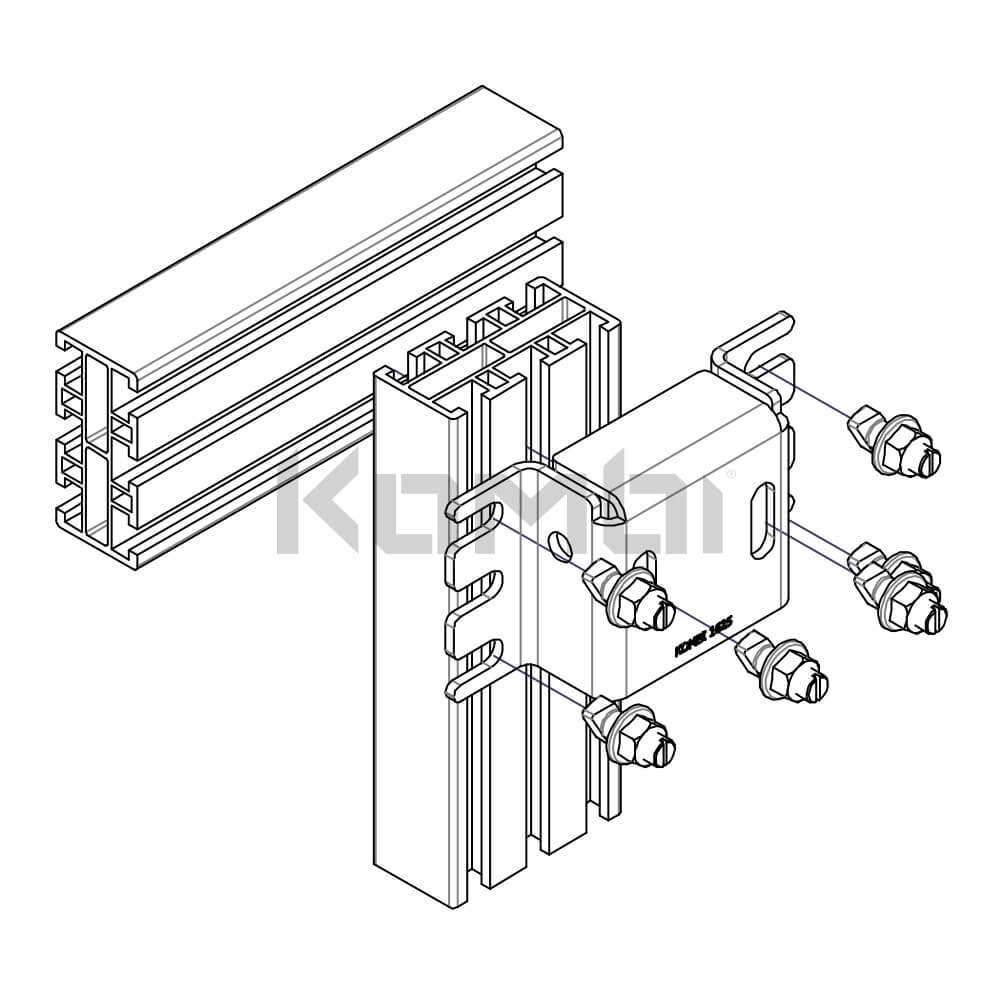

KOMBI 80 Angle Bracket

Code

KB013.80

Material

Powder coated stainless steel

Use

90 Degree KOMBI 80 corners

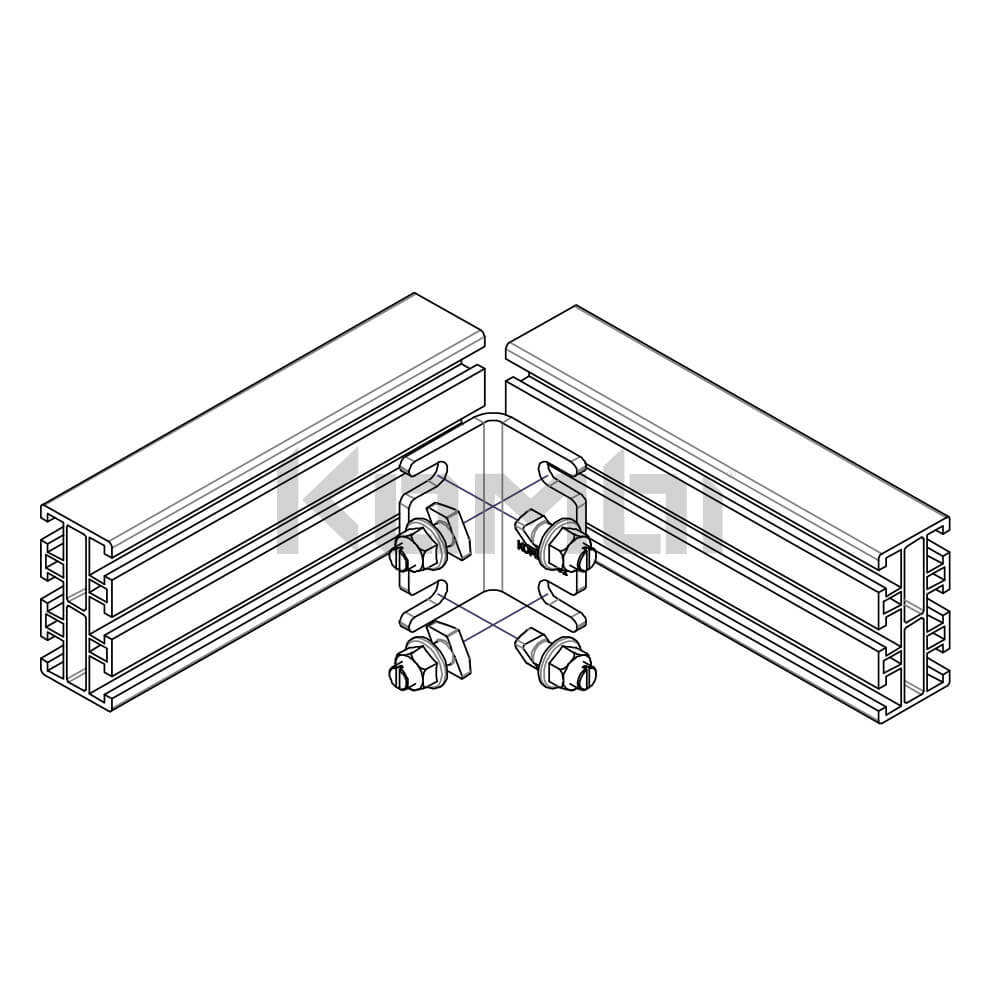

KOMBI 180 Angle Bracket

Code

KB013.180

Material

Powder coated stainless steel

Use

90 Degree KOMBI 180 corners

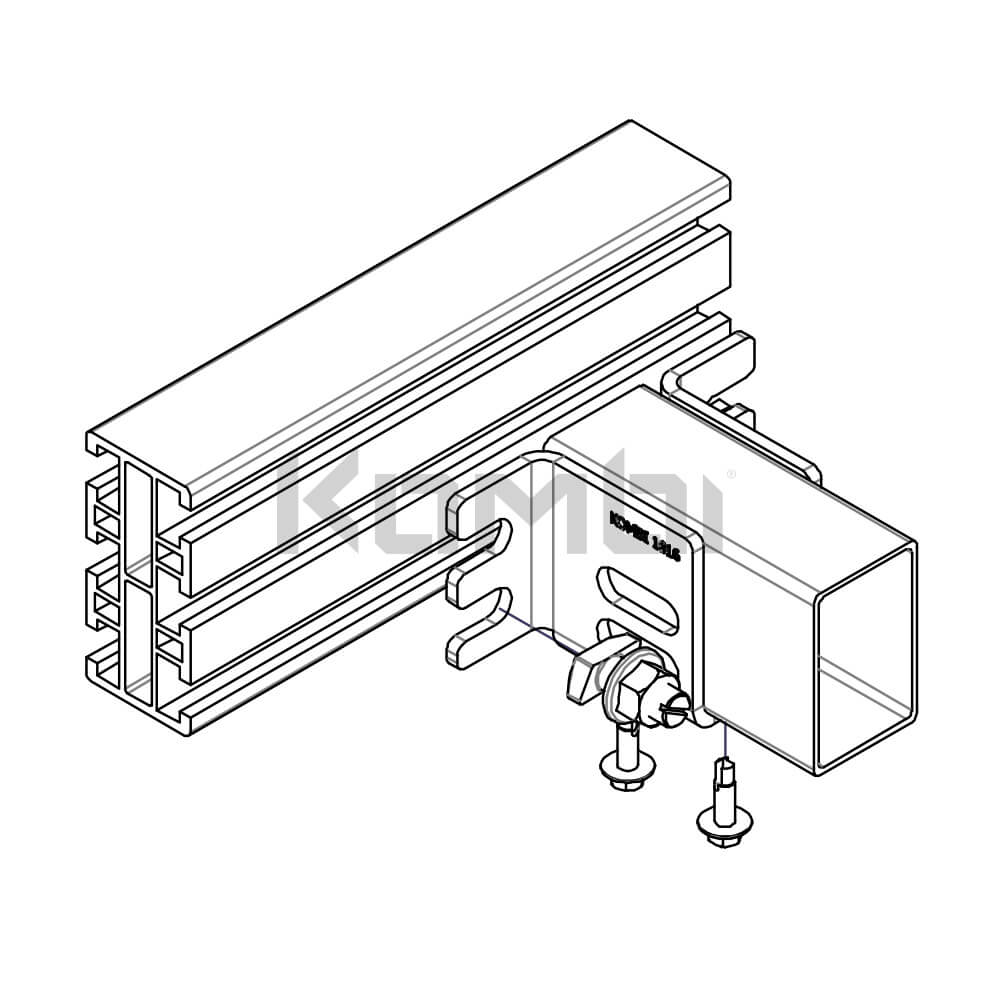

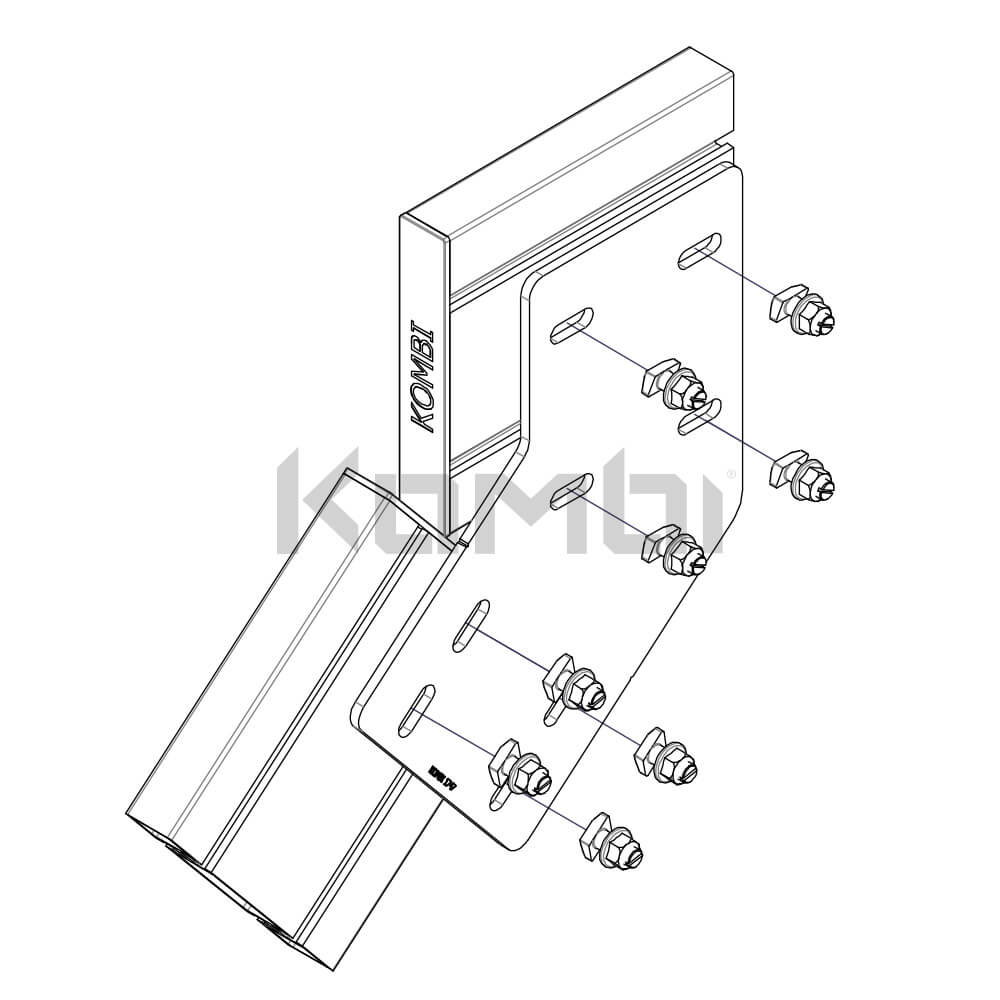

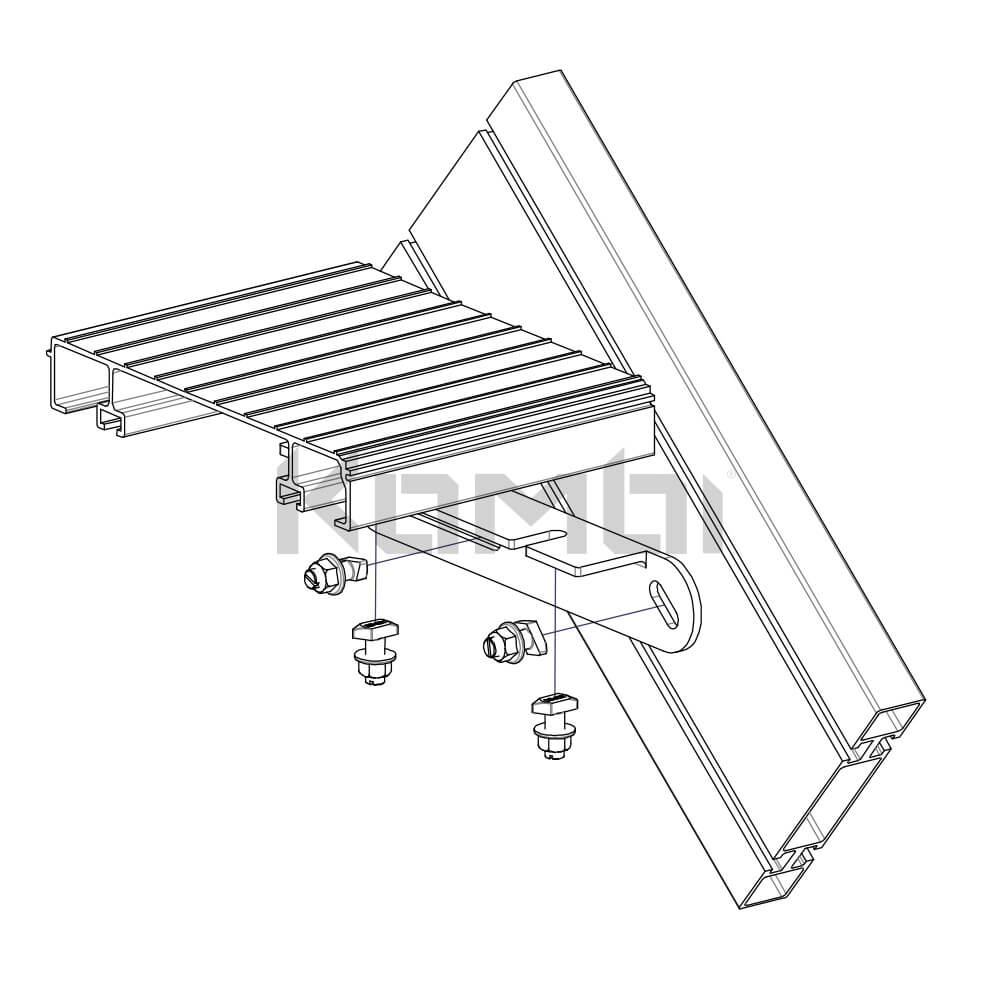

KOMBI 80 Stair Bridge Mounting Plate

Code

KB014

Material

Powder coated stainless steel

Use

Connects stair stringer to platform structure

KOMBI 180 Angle Bracket Kit 45 Degrees

Code

KB015.80

Material

Powder coated stainless steel

Use

KOMBI 45 degree angle corners

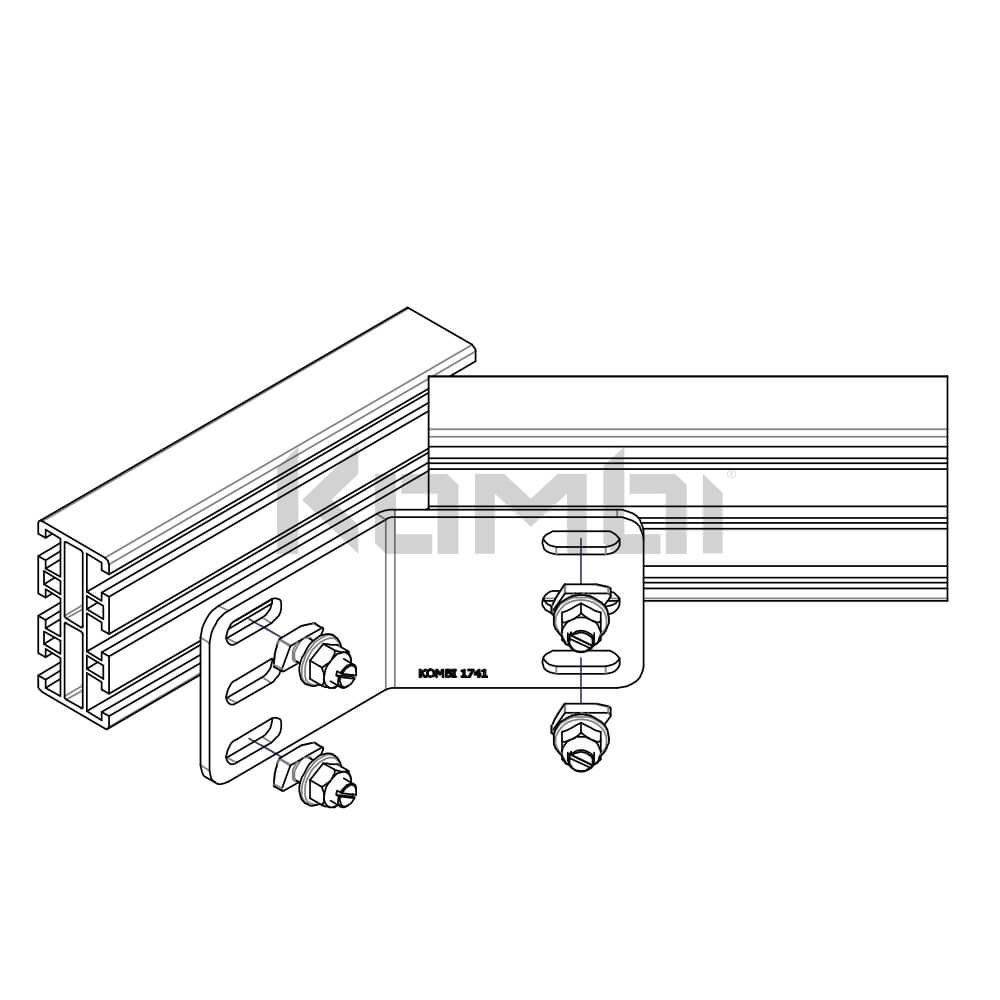

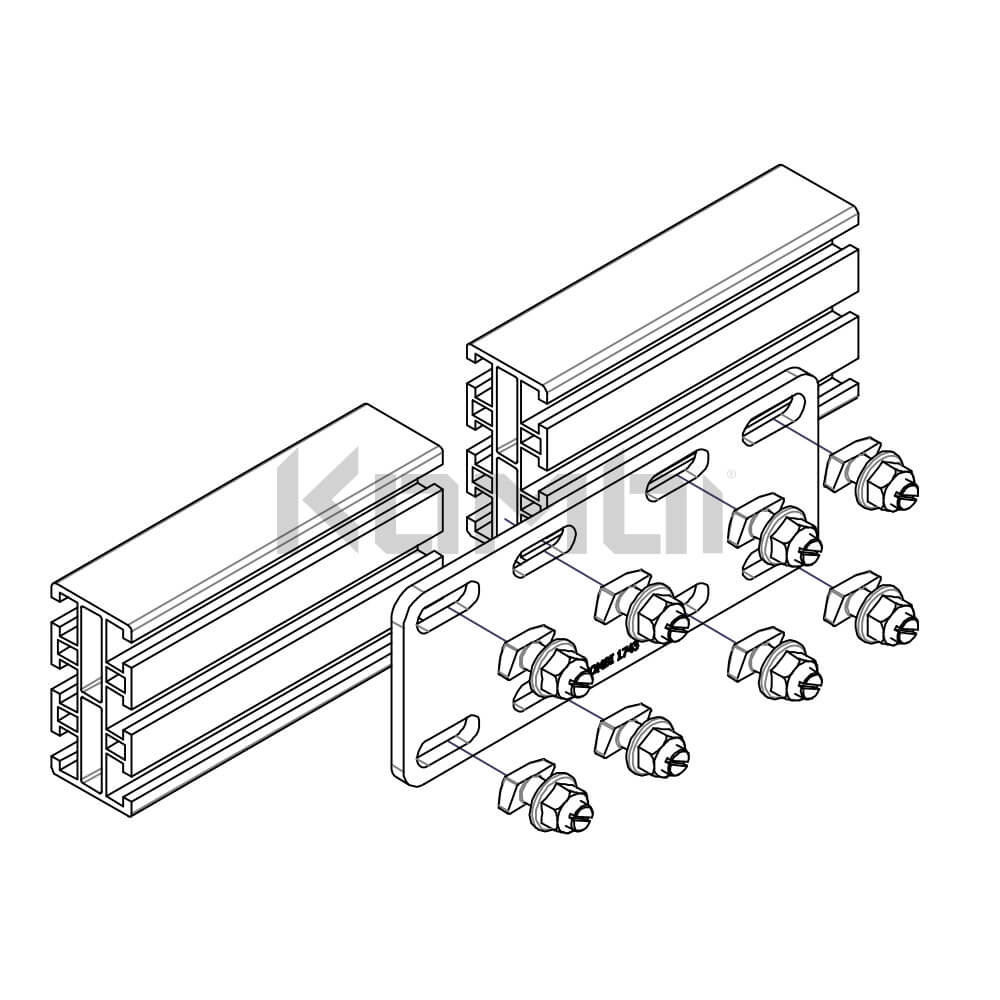

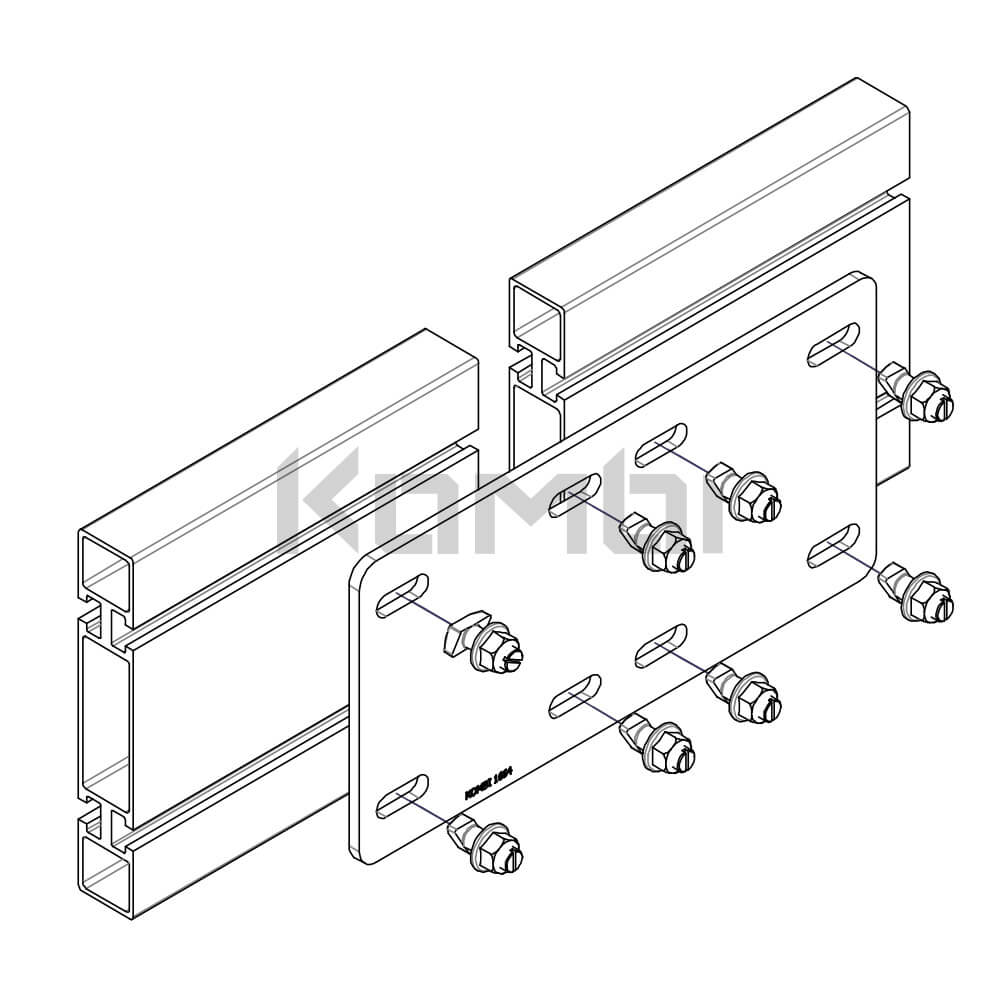

KOMBI 80 Post Joining Plate

Code

KB016.80

Material

Aluminium

Use

Joins KOMBI 80 extrusion

KOMBI 180 Joining Plate

Code

KB016.180

Material

Aluminium

Use

Joins KOMBI 180 extrusion

KOMBI Stair Tread Connection Bracket

Code

KB019

Material

Aluminium

Use

Connects stair tread to stringers

KOMBI 80 Top Support Bracket

Code

KB021

Material

Powder coated stainless steel

Use

Connects KOMBI 80 post to platform

KOMBI 80 Post Through Bracket

Code

KB022

Material

Powder coated stainless steel

Use

Connects KOMBI 80 post to platform

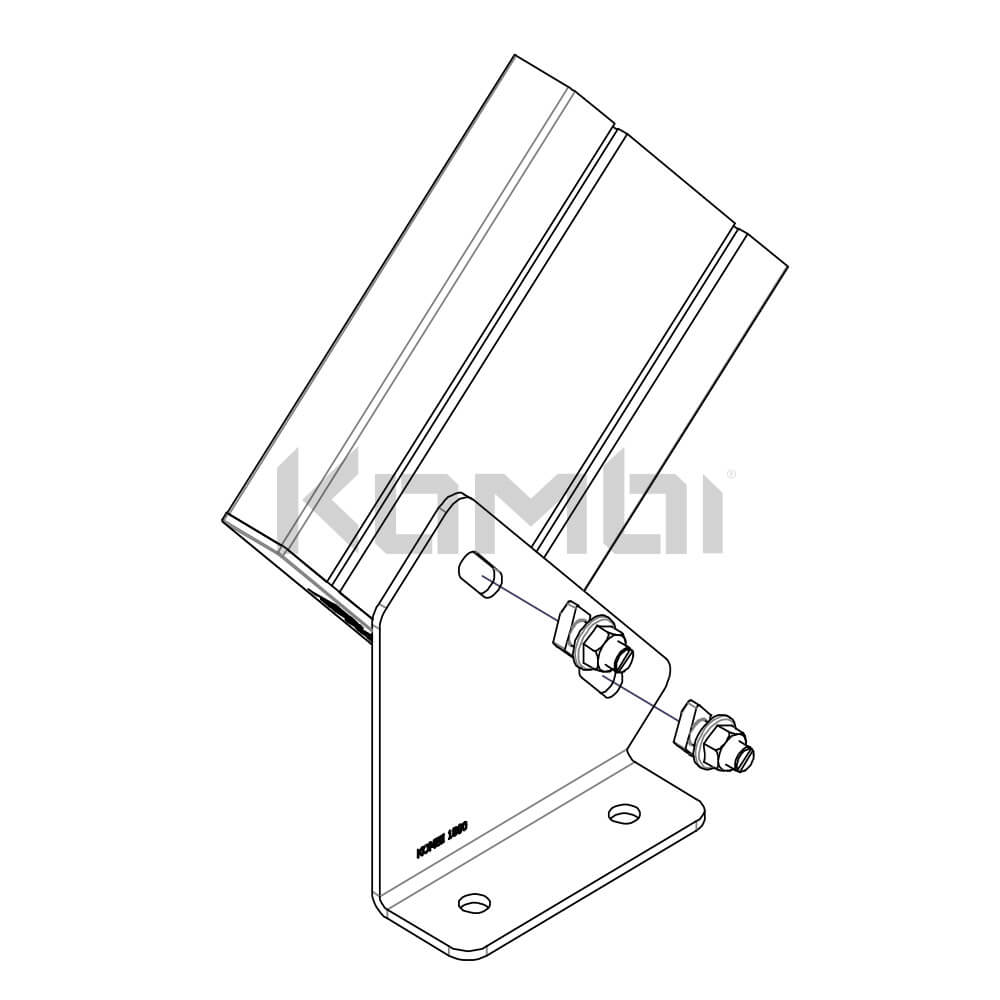

KOMBI 80 Base Support Foot

Code

KB026

Material

Powder coated stainless steel

Use

Secures KOMBI post to ground

KOMBI Stair Bridge Mounting Plate

Code

KB034

Material

Powder coated stainless steel

Use

Connects stair stringer to platform structure

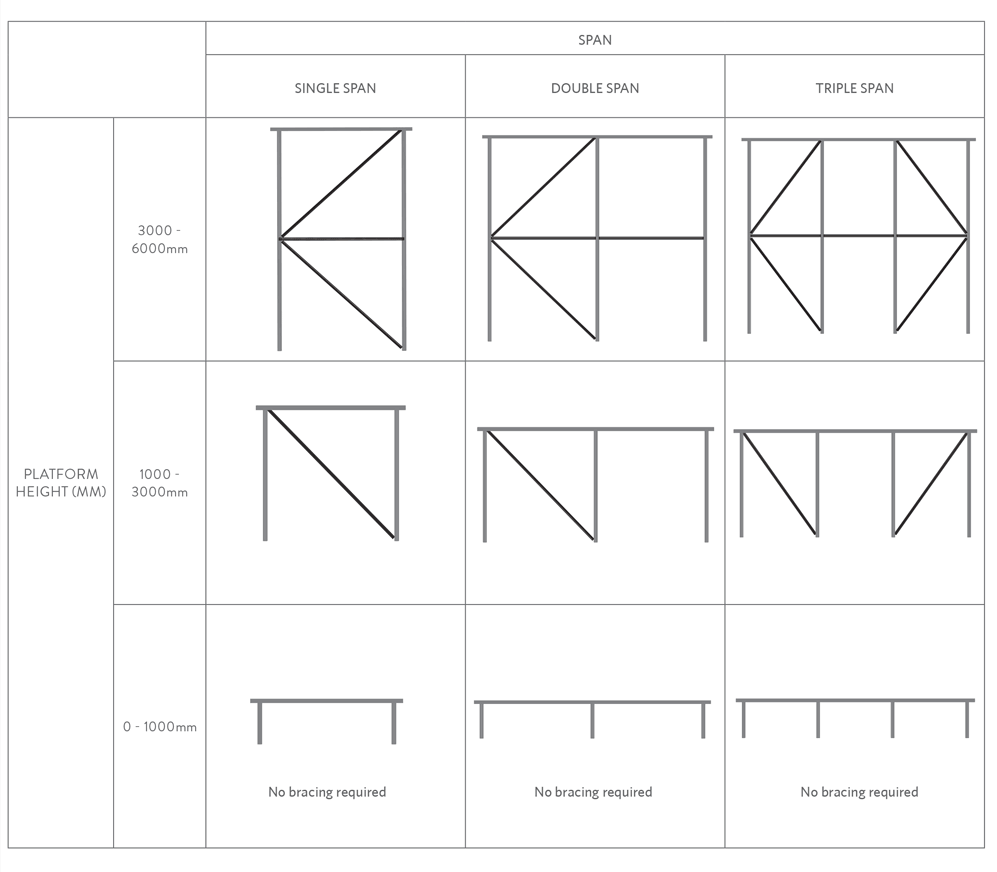

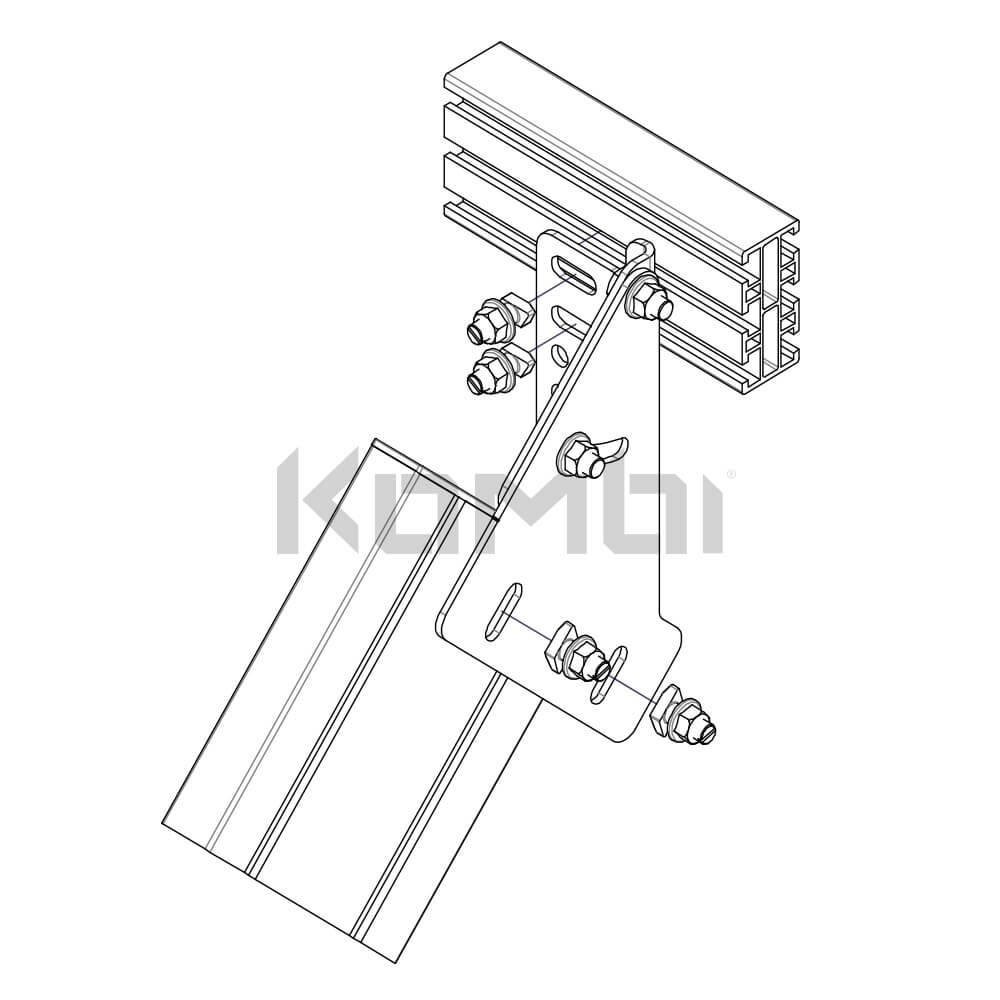

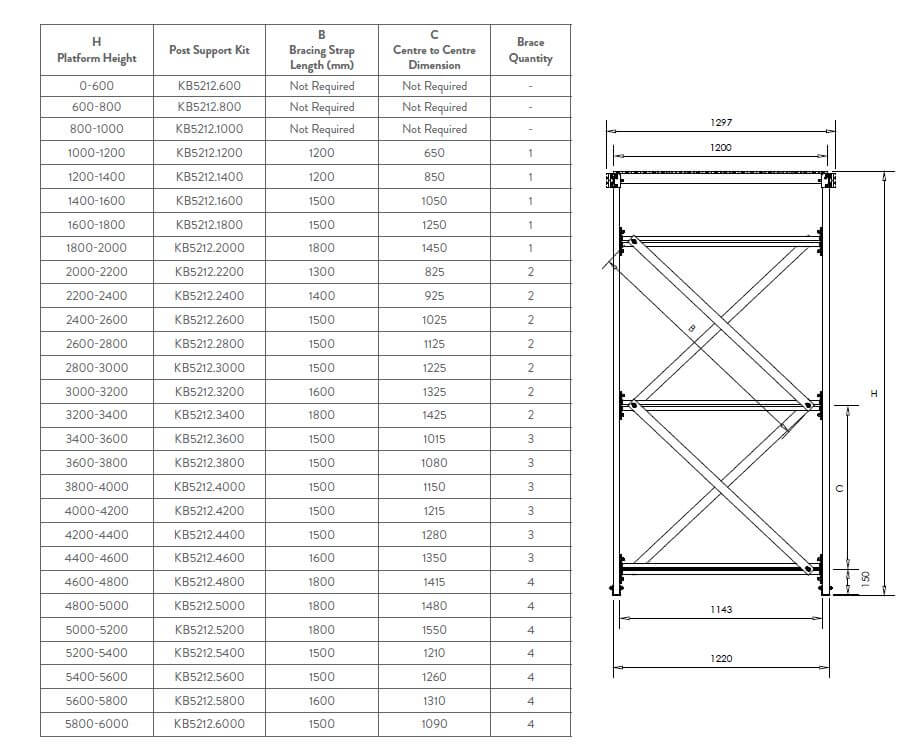

Post Support Bracing Layout

Instructions For Layout

- Step 1: Identify correct post height.

- Step 2: Determine correct post support kit.

- Step 3: Assemble post support bracing as per tables below.

900 Series Bracing Layout

1200 Series Bracing Layout

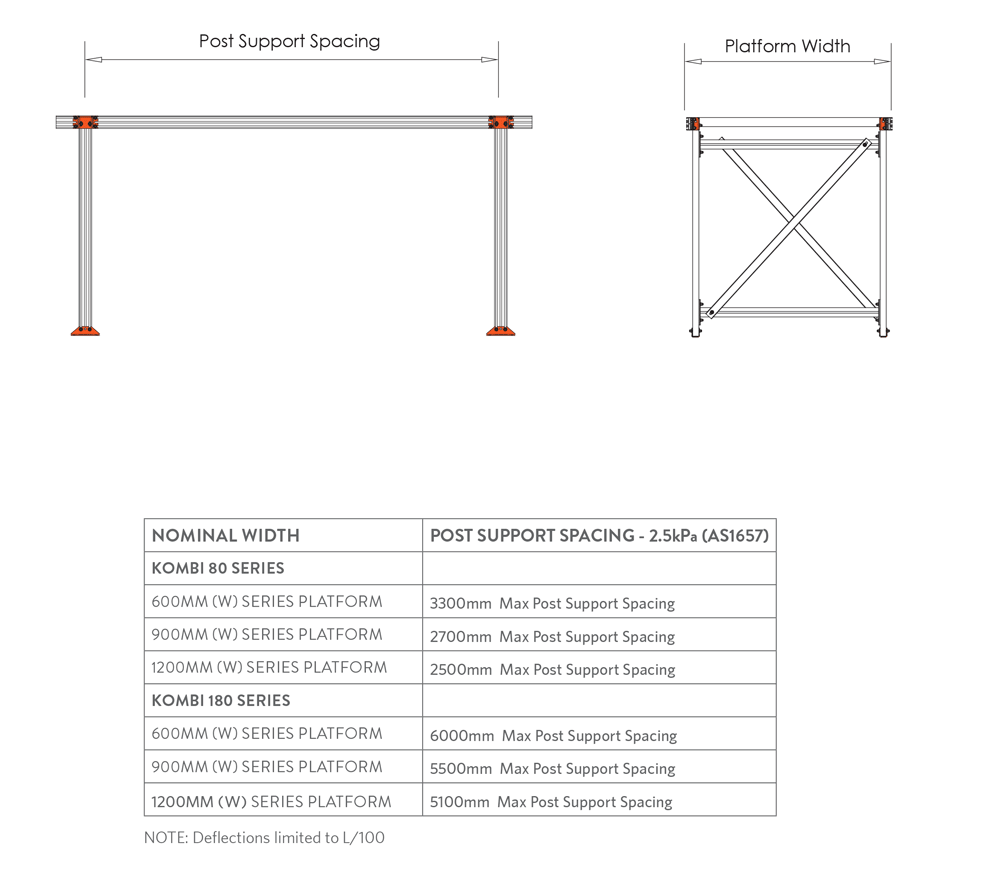

Post Support Span Table

Post Support Spacing Information

- KOMBI Platforms are designed to support a live load of 2.5kPa (250kg/m2).

- Calculations assume maximum flooring mass of 12kg/m2 (weight of guardrail and aluminium deck).

- Allowance for floor vibration has not been taken into account in design.

- Platform deflection has been based on two variables, frequent access (less deflection) and infrequent access (greater deflection). Table below shows post spacings based on above.

- Lateral bracing is required as per configuration tables.

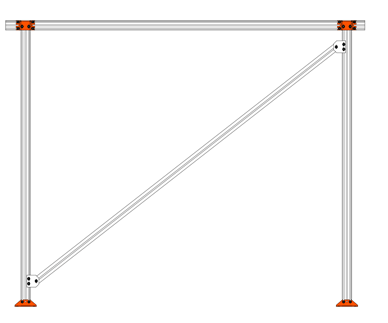

Lateral Brace Layout

Lateral Brace Installation

Lateral Brace Installation

- KOMBI Platform proprietary design allows freestanding platforms of up to 6000mm.

- Platforms above 3000mm require a horizontal brace mid span of the post in all bays.

- For longer platforms exceeding triple span, up to 30m, lateral bracing is require in the first and last bay only.

- For longer platforms from 30m - 50m, lateral bracing is required in the first, centre and last bay only.

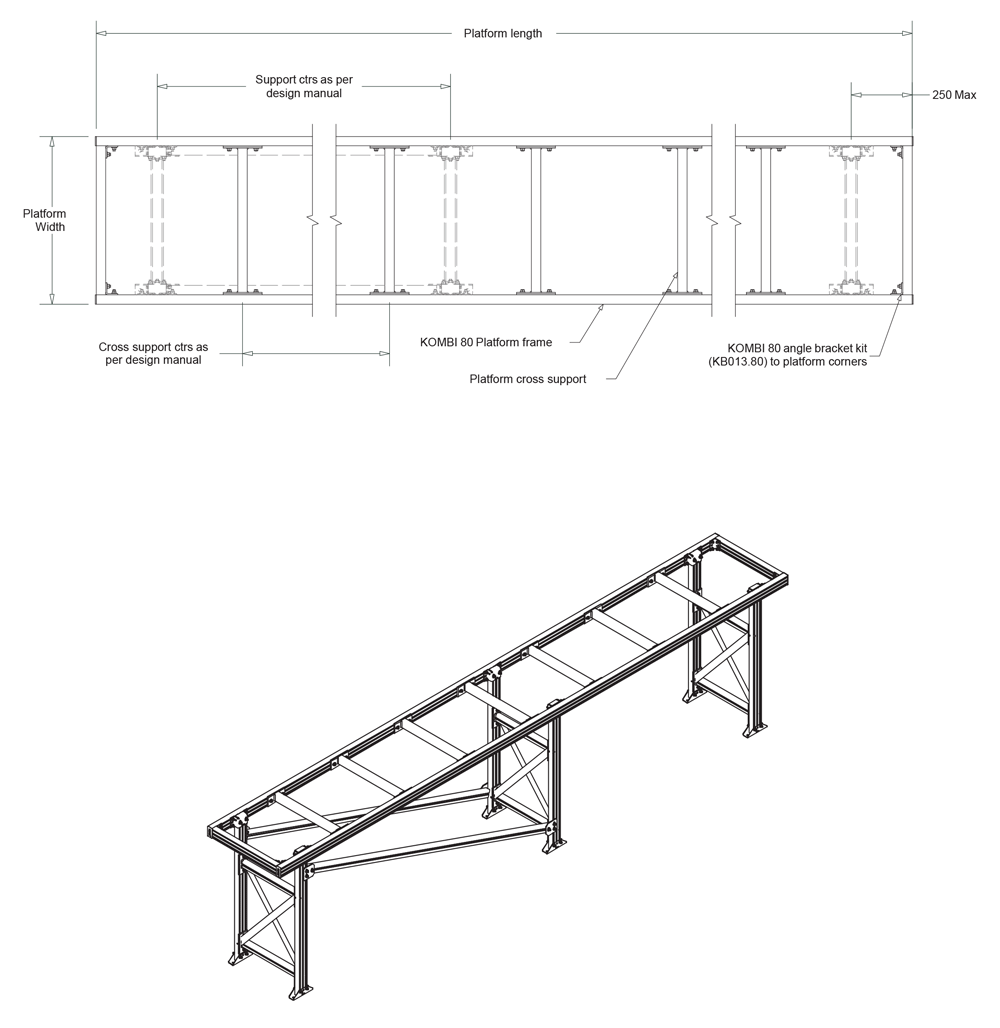

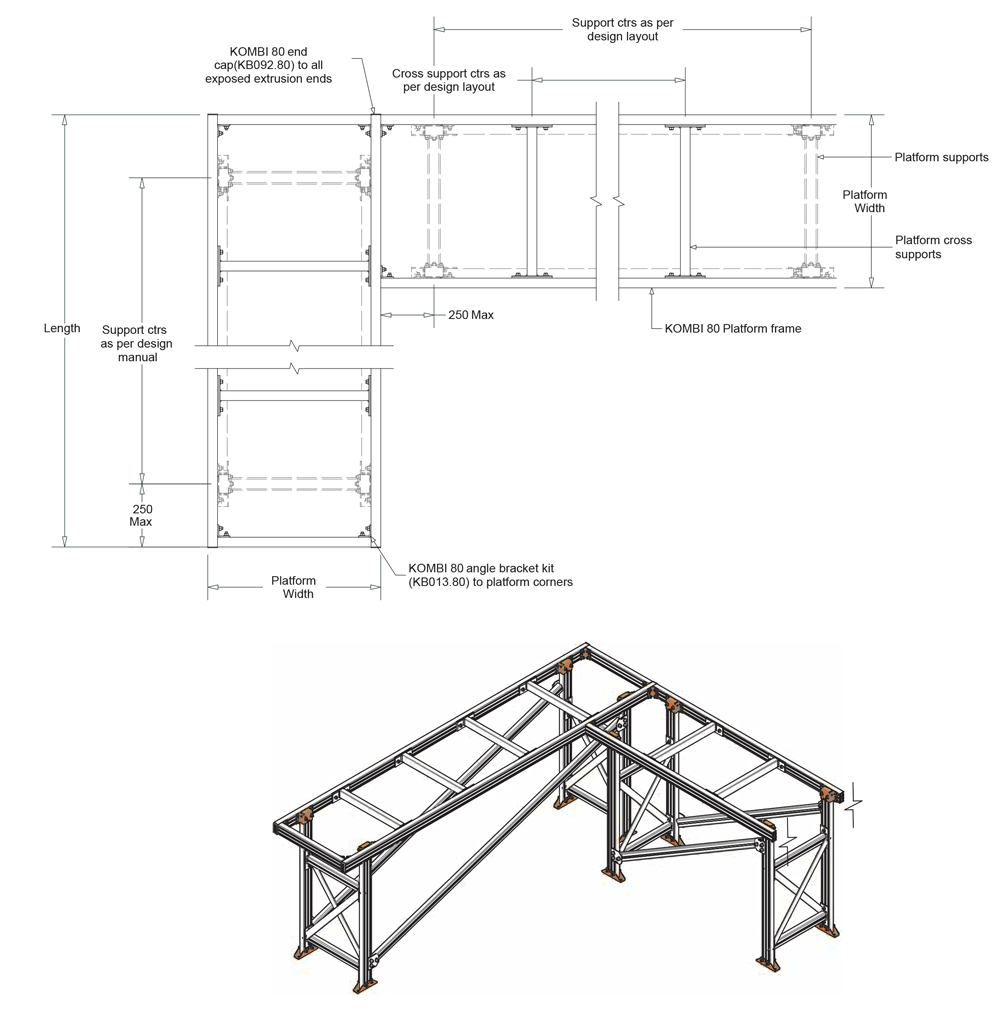

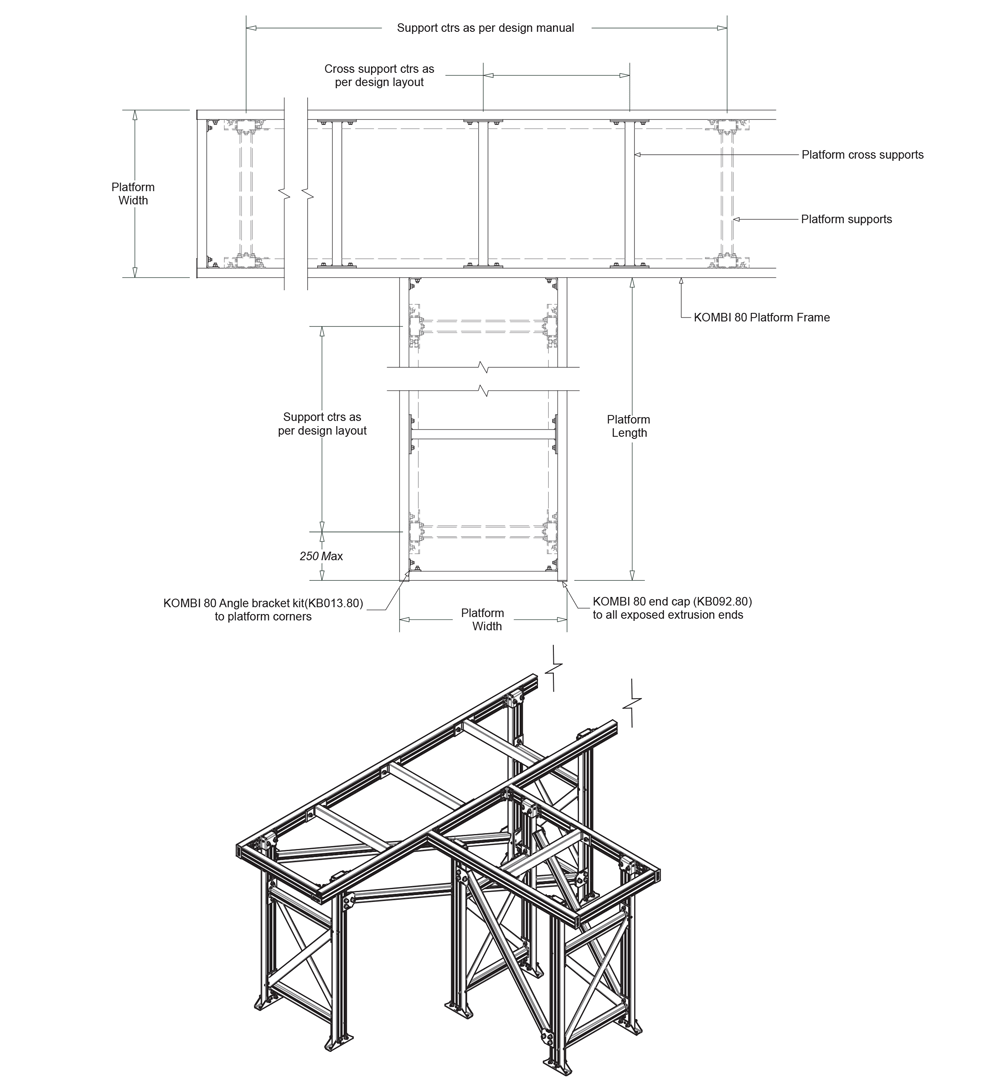

Platform Configuration

Platform Set Out Guidelines

- Platform cross supports positioned at 600mm centres.

- Post supports positioned as close to end of platform as possible. (250mm max from outside edge of platform to centre of post.)

Platform Set Out Guidelines

- Platform cross supports positioned at 600mm centres.

- Post supports positioned as close to end of platform as possible. (250mm max from outside edge of platform to centre of post.)

Platform Set Out Guidelines

- Platform cross supports positioned at 600mm centres.

- Post supports positioned as close to end of platform as possible. (250mm max from outside edge of platform to centre of post.)

Technical Statement

Download a copy of the KOMBI® Technical Statement

| CRITERIA | DATA | NOTES |

| ALUMINIUM EXTRUSION | ||

| KOMBI 180 | Aluminium Grade 6005A-T5 | |

| KOMBI 80 | Aluminium Grade 6005A-T5 | |

| KOMBI 60 | Aluminium Grade 6106-T6 | |

| Bracing Straps | Aluminium Grade 6106-T6 | |

| Walkway Mesh | Aluminium Grade 6106-T6 | |

| Handrail | Aluminium Grade 6106-T6 | |

| Kneerail | Aluminium Grade 6106-T6 | |

| Toe Board | Aluminium Grade 6106-T6 | |

| Stainless Steel Brackets | Stainless Steel Grade 316 | |

| Aluminium Brackets | Aluminium Grade 5083-T5 | |

| PLATFORM LOADINGS | ||

| Live Load | 2.5kPa | In accordance with AS 1657:2018 |

| Concentrated Loading | 1.1kN | Applied through 100 x 100 pad at any point |

| Mesh Slip Rating | R11 | |

| Max Free Standing Height | 6000mm | Subject to Sayfa technical advice |

| Platform Support Spans | KOMBI 80 SERIES | Deflection limited to the span length divided by 100 |

| 600 Series (W) Platform - 3300mm max spacing | ||

| 900 Series (W) Platform - 2700mm max spacing | ||

| 1200 Series (W) Platform - 2500mm max spacing | ||

| KOMBI 180 SERIES | ||

| 600 Series (W) Platform - 6000mm max spacing | ||

| 900 Series (W) Platform - 5500mm max spacing | ||

| 1200 Series (W) Platform - 5100mm max spacing | ||

| Platform Mesh Openings | Personnel access under platform | Where personnel is required to access underneath platform narrow mesh (GW334) must be used. |

| STAIR LOADINGS | ||

| Live Load | 2.5kPa | Applied to tread and landing |

| Deflection | L/100 or 40mm | Whichever is the lesser |

| Tread Loadings | 2.2kN per lineal metre or a concentrated loading of 1.5kN | In accordance with AS 1657:2018, Section 7.1.1 |

| Max Stair Treads | 17 treads, 18 risers | In accordance with AS 1657:2018 |

| Stair Widths | Max 1500mm wide | |

| Stair Angles | 26 degrees to 44 degrees | Ideal angle is 40 degrees. Angle can be increased to reduce footprint. |

| Stair Risers | Riser - 130 ≤ R ≤ 225 | All risers and goings in the same flight of stairs shall be uniform dimensions within a tolerance of ± 5mm |

| Going - 215 ≤ G ≤ 255 | ||

| Combination = 540 ≤ (2R + G) ≤ 225 | ||

| DESIGN WIND CRITERIA | ||

| Region | A1 | |

| Regional Gust Wind Speed | V100 = 41m/s | |

| Terrain Category | 2 | |

| Topographical Multiplier | MT = 1.0 | |

| Terrain/Height Multiplier | Mzcat = 0.96 | |

| Shielding Factor | MS = 1.0 | |

| FASTENERS | ||

| Material | Stainless Steel 316 | |

| KOMBI T-Bolt Fixing | M10 x 25mm, 316 SS | |

| KOMBI Nut Torque | 60nM | |

| HANDRAIL | ||

| Platform Guardrail Post Spacing | 2000mm Max | |

| Max Handrail Height | 1000mm | Typically 987mm standard from deck to top of handrail |

| Kneerail Height Below Top Rail | 450mm from top of kneerail to underside of kneerail | |

| Platform Toe Board | Use KOMBI GW320 | Required if an object could fall from a platform or landing onto an area to which access by persons is available. |

| Limitations of Use | Not suitable for BCA / NCC stair design. | |

| DISSIMILAR METALS | ||

| Aluminium to Concrete | To be painted with a bitumen paint. | |

| Aluminium to Roof Deck | Shall be separated with EPDM tape. | |

| Aluminium to Stainless Steel | Brackets to be powder coated or EPDM separated. | Note: This does not apply to fasteners. Ref AS/NZS 1664.1:1997 Section 5.1. |

| WEIGHT | ||

| Walkway Mesh 13mm x 600mm Wide | 6.5kg / m2 | |

| KOMBI 80 Extrusion | Approx 2.8kg / m | |

| KOMBI 180 Extrusion | Approx 4.2kg / m | |

| KOMBI Platform including Walkway Mesh | Approx 18kg / m2 Excluding Handrails | This is an approximate weight only. Depending on different combinations this can vary. |

CLICK HERE TO DOWNLOAD A COPY OF THE KOMBI TECHNICAL STATEMENT

Lateral Brace Installation

Lateral Brace Installation