The importance of maintaining your cooling towers

Neglecting cooling tower maintenance can be a costly and dangerous exercise. Routine checks need to be conducted to ensure that you are getting the best out of your machines and providing a clean and safe work environment and complying to Regulations*.

Health & Safety

Legionella or other bacteria borne illnesses can spread quickly through air conditioning systems so it is vital that they are kept clean and tested often to avoid any dirty, untreated water getting into the system.

Performance

A well serviced cooling tower system is like a car. Keep up with the services, address any problems early and you will have a unit that always performs at its best.

Longer Lasting

Just as regular maintenance helps with the performance, it also will ensure that issues that could cause undue or excessive wear and tear on your cooling tower systems are discovered early and corrected.

More Economical & Efficient

If a unit is working at optimum performance it will also give the best results. Minor damage or faults can impact performance and if left go they can also cost money, both in running costs and repairs.

Industry Compliance

Cooling towers must be compliant and maintained in accordance with government Regulations* and Australian Standard AS/NZS 3666: Air-handling and Water Systems of Buildings—Microbial control.

Your responsibilities

If you are a PCBU (Person Conducting a Business or Undertaking), building owner, manager or employer you have a duty of care to ensure, so far as is reasonably practicable, that all personnel who conduct work on your buildings do so safely.

According to the Public Health and Wellbeing Regulations 2019*, cooling tower system routine service and testing obligations are as follows:

- A responsible person must ensure that a cooling tower system is serviced at least once each month to determine whether the cooling tower system is operating without defects.

- A responsible person must ensure that at least once each month a sample of recirculating water is taken and provided to a laboratory to determine the heterotrophic colony count of the recirculating water.

- A responsible person must ensure that at least once every 3 months a sample of recirculating water is taken and provided to a laboratory to test for Legionella.

- An assessment of the risk of Legionella contamination and preparing a Risk Management Plan (RMP) must be completed every 5 years (or more frequently if required).

- An independent audit of compliance with the Risk Management Plan and Regulation to be completed yearly.

Failure to perform these mandatory checks can result in hefty fines but more importantly can leave your cooling towers unsanitary and unsafe. No-one wants to see outbreaks of Legionnaire's Disease and this is just one side effect of not performing regular cleaning and maintenance of your cooling tower and water treatment plants.

With the introduction of Workplace Manslaughter Laws, there is even potential that should an outbreak of something such as deadly as Legionnaire's Disease occur in one of your buildings, you could be held liable for any deaths as a result of that illness.

*Part 6, Division, Section 70 of the Public Health and Wellbeing Regulations 2019

How often are you servicing & testing your cooling towers?

If the answer is less than the above regulatory requirements, it begs the question, why? Month, quarterly and yearly maintenance, testing and inspection of your cooling towers is onerous but it is an essential part of your duty of care. If it is not being conducted, could it be because of any of these reasons?

- Access is so difficult that employees and contractors just can't get to machinery.

- There is no safe way to perform the duties and workers must take unnecessary risks, making them reluctant or even refusing to do the work.

- Systems installed are old, non-compliant and dangerous.

- Systems are cumbersome and do not allow easy access to the equipment making it nearly impossible to carry out maintenance or testing.

- Systems are difficult to use and require personnel with higher skill levels to be able to operate them.

Access to cooling towers is quite often difficult. Sometimes they may be located in confined spaces and other times there may be a requirement to work at height. If working at height is necessary then access systems need to offer the worker fall protection.

Because of the regularity of access required to your cooling towers, it is important that the access systems you have are user friendly, durable and allow work to be carried out effectively.

KOMBI - Your Access Solution

An effective solution for access to cooling towers can be provided by the installation of access platforms, stairs, crossovers and elevated walkways.

Systems that can be installed on-site without the need for hot works or specialist trades, speed up installation and allow assembly to be carried out in difficult to reach or constricted areas. In the case of remote locations, it can often be impossible to get exact measurements prior to installation and systems may go to site, only to be returned as they cannot be assembled due to being produced to the incorrect size.

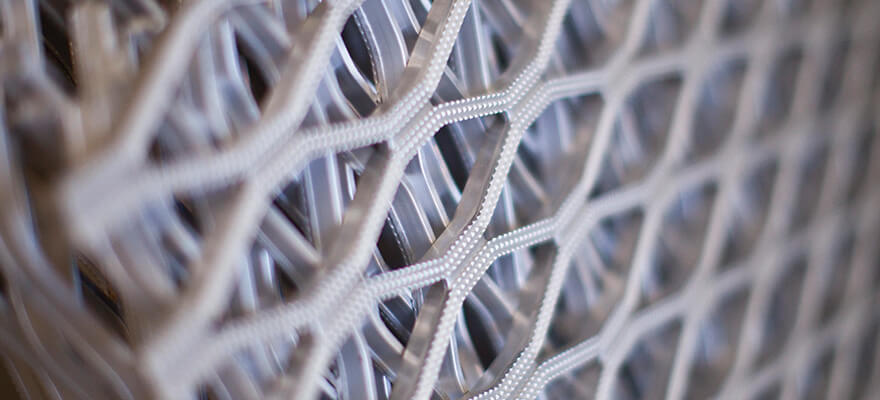

This is the beauty of KOMBI. Our access platforms, stairs, crossovers, elevated walkways and suspended platforms/walkways are constructed of lightweight aluminium and their modular design ensures that whatever the requirement, KOMBI can be modified to suit. Delivered flat packed to site, final adjustments can be made simply by using the unique KOMBI patented T-Bolt.

With the help of our comprehensive and easy to follow manual, which gives step by step instructions, specialist trades and tools are not required. A huge cost saving advantage!

You can also be comfortable in the knowledge that all KOMBI systems are manufactured and designed in accordance with Australian Standard AS/NZS 1657:2018.

For more details on how KOMBI can solve your access problems, contact us on 1300 072 651 or info@kombiaccess.com.

For more information read:

- Case Study – HydroChem, Braeside

- Case Study - Mirvac Property Group

- Case Study - Victorian Comprehensive Cancer Centre